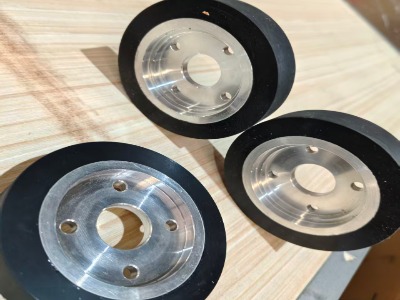

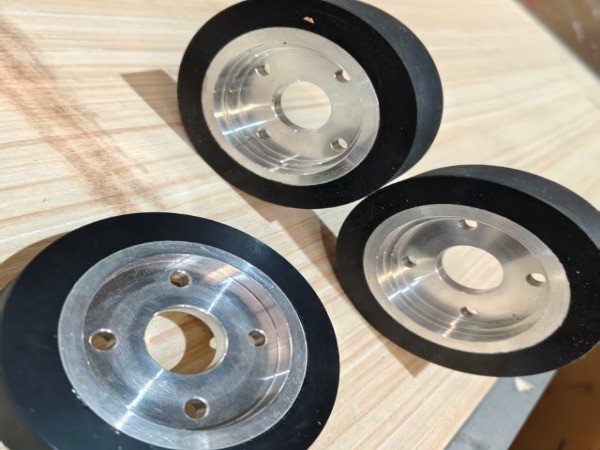

High-Performance Friction Wheels

Our high-precision friction wheels reduce friction through advanced material selection and radial loading. Ideal for AGVs, conveyors, and precision instruments.

Technical Information

In mechanical design, a Fixed Platform Friction Wheel is a mechanism that transmits motion and power through direct contact between two surfaces, leveraging frictional force. Known for its simple structure, smooth operation, and inherent overload protection, it is widely utilized in light industrial machinery, precision instrumentation, and automated material handling equipment.

However, friction is a double-edged sword: it is the source of power but also the root cause of energy loss and wear. To enhance system efficiency, it is critical to optimize wheel contact and minimize parasitic frictional resistance.

How to Reduce Friction on Wheels?

In friction drive systems, reducing friction refers to minimizing parasitic drag at the bearings and optimizing rolling friction at the contact interface to ensure efficient power transmission and reduce heat buildup. Key optimization strategies include:

Optimizing Surface Materials: Select materials with high hardness and low hysteresis loss. For instance, using polyurethane-coated friction wheels on fixed platforms provides sufficient grip while reducing rolling resistance caused by material deformation.

Improving Manufacturing Precision: Ensure strict control over wheel roundness and surface roughness. Irregular profiles lead to periodic vibration and energy dissipation.

Precise Radial Loading: While friction wheels require normal force to transmit torque, excessive pressure overloads the bearings. Using precision springs or hydraulic mechanisms to apply "optimal" pressure minimizes unnecessary friction.

Maintaining a Clean Environment: Dust or oil at the contact point can alter the friction coefficient, leading to slippage or abnormal wear.

What are the 4 Ways of Reducing Friction?

From a broad physics and mechanical engineering perspective, there are four core methods to reduce friction in any rotating or sliding system:

Lubrication: Introducing oil, grease, or solid lubricants (like graphite) between contact surfaces converts dry friction into fluid or boundary friction. Note: While the contact faces of friction wheels must remain dry, lubrication is vital for their supporting bearings.

Rolling instead of Sliding: This is the fundamental principle of the wheel and axle. Using ball or needle bearings to support friction wheels on fixed platforms significantly reduces resistive torque.

Material Selection: Choosing material pairs with low friction coefficients (such as Teflon or ceramics) or increasing surface hardness through heat treatment reduces molecular adhesion.

Fluid or Magnetic Levitation: In high-end precision platforms, air bearings or magnetic force are used to separate surfaces, almost entirely eliminating mechanical contact friction.

Industry Applications of Friction Drives

Friction drives are indispensable across various sectors, from daily applications to heavy industry, due to their quiet operation and safety features:

Industrial Conveying & Automation: In modern factories, friction wheels are core components for smooth material movement.

AGVs (Automated Guided Vehicles): Many mobile robots use polyurethane friction wheels for drive and steering to ensure high traction and low-noise operation.

Mine Hoists: Friction-type hoists (such as multi-rope friction winders) utilize the friction between wire ropes and liners to lift ore and personnel.

Amusement Rides: Many roller coasters use friction wheels (Drive Tires) in station areas or lift hills to control acceleration, braking, and precise positioning.

Looking to customize the most efficient drive solution for your fixed platforms? Friction wheel design directly impacts equipment energy efficiency and service life. Our engineering team brings extensive expertise in material matching and pressure compensation design. [Contact us for a free drive system evaluation]

You have questions, we have answers. Contact us today. Our skilled customer service specialists can help you make the right choice in polyurethane applications.

AGV Steering Drive Wheels: Polyurethane on Cast Iron Units

Industrial Polyurethane Elastomer Wheels