-

WhatsApp: +86 19941574798

WhatsApp: +86 19941574798

-

sale06@kfqizhongji.com

sale06@kfqizhongji.com

Material Handling Drive System

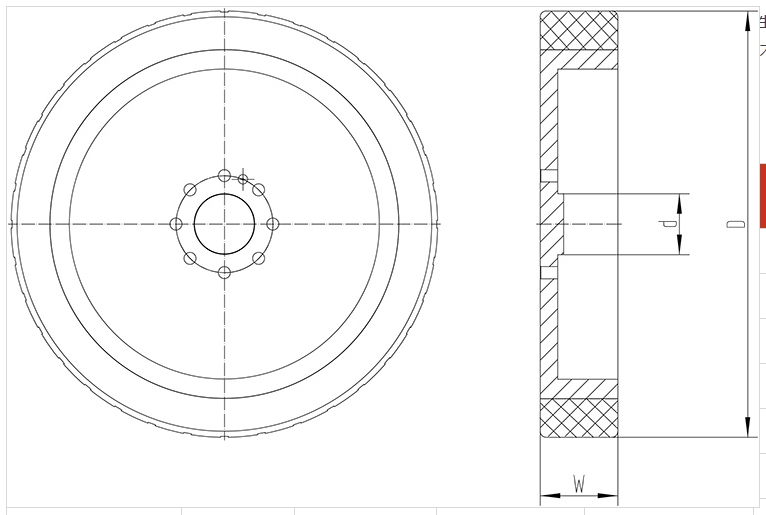

Rail-Guided Vehicle (RGV) PU Wheels in Automated Material Handling

Rail-guided vehicle (RGV) PU wheels are critical components in automated material handling systems, facilitating efficient and reliable transportation within warehouses and industrial environments.

In the fast-paced world of automated material handling, Rail-Guided Vehicles (RGV) and Shuttle systems are the backbone of warehouse efficiency. At the core of these systems lie the Polyurethane (PU) wheels. These aren't just components; they are critical engineered solutions designed to ensure reliability, speed, and long-term ROI.

1. Engineered for Endurance: Load Capacity & Durability

RGVs often operate 24/7 under significant stress. Our poly-coated wheels are formulated to tackle these demanding cycles:

High Abrasion Resistance: The advanced PU coating prevents "flat spots" and premature wear, even under high-frequency start-stop cycles.

Superior Tear Strength: Engineered to withstand heavy loads without delamination, ensuring your automated system stays online longer.

Impact Resilience: Absorbs the mechanical stress of high-speed transitions, protecting the vehicle’s internal drive components.

2. Silent & Smooth: Noise Reduction & Floor Protection

Modern smart warehouses prioritize both equipment longevity and operator environment.

Vibration Dampening: The viscoelastic properties of polyurethane absorb shocks, significantly reducing the decibel levels of warehouse operations compared to nylon or steel wheels.

Zero-Marking Technology: Unlike rubber, high-quality PU preserves the integrity of your floor coatings and tracks, preventing costly surface repairs and maintaining a clean facility.

3. Energy Efficiency through Low Rolling Resistance

Efficiency isn't just about speed; it's about energy consumption.

Optimized Power Usage: Our wheels are designed with a low rolling resistance coefficient. This means the RGV requires less torque to initiate movement and less energy to maintain speed.

Heat Dissipation: Advanced formulations (such as NDI-based PU) minimize internal heat buildup (hysteresis), which is the primary cause of wheel failure in high-speed shuttle applications.

4. Customization: Tailored for Your Logic

No two warehouses are identical. We provide a versatile range of customization options to fit your specific RGV architecture:

Hardness Tuning: Ranging from 75 Shore A to 95 Shore D to balance grip and load capacity.

Core Materials: High-strength steel, aluminum, or cast iron hubs depending on weight requirements.

Environment-Specific Formulas: Specialized coatings for cold storage (-30°C) or high-humidity environments.

Why Quality Matters

Investing in premium PU wheels is an investment in system uptime. Cheap alternatives lead to frequent maintenance shutdowns, increased energy bills, and potential damage to expensive rail infrastructures. By choosing high-performance polyurethane solutions, you ensure a streamlined, cost-effective, and reliable automated future.

Categories

Recent Cases

Recent Products

Recent Blogs

- How Do Polyurethane Wheels Compare To Metal Wheels

- Why Choose Injected Polyurethane (TPU) Wheels for Your Equipment

- Why Roller Coasters Use NDI Polyurethane Wheels

- How to Choose a Poly Wheels Manufacturer That Won't Fail

- Why Polyurethane is the Choice for Pallet Jack and Forklift Wheels

- Pallet Stacker Drive & Idler Wheels for Automated Warehouses

- Mold-on Polyurethane Wheels

- Analysis of the Causes of Cleanroom Stacker Polyurethane Wheel

- Why Are NDI Drive Rollers the Premier Choice for Pallets

- Polyurethane Wheels in Mining

Polyurethane Wheels Improve Efficiency in Automated Sorter Systems

High-performance Polyurethane AGV Drive Wheels