-

WhatsApp: +86 19941574798

WhatsApp: +86 19941574798

-

sale06@kfqizhongji.com

sale06@kfqizhongji.com

How Do Polyurethane Wheels Compare To Metal Wheels

Compare polyurethane (PU) wheels and metal wheels in terms of load capacity, durability, noise, and floor protection. Discover which wheel type is best for cranes, AGVs, forklifts, systems to improve performance and reduce maintenance costs.

In the world of industrial handling and material transport, the choice of wheel material can greatly impact performance, durability, and cost-efficiency. Among the most common options, polyurethane (PU) wheels and metal wheels stand out for their contrasting characteristics. Understanding their differences helps engineers, maintenance teams, and buyers select the most suitable solution for each application.

1. Material Composition and Core Features

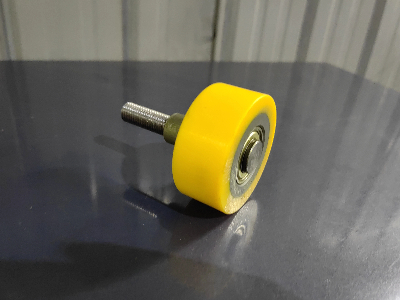

Polyurethane wheels are made from a synthetic elastomer that combines the elasticity of rubber with the toughness of plastic. They are often bonded to a steel or aluminum core, offering both flexibility and strength.

Metal wheels, on the other hand, are usually made from steel, cast iron, or forged alloys. They are rigid, durable, and designed to carry extremely heavy loads under harsh industrial conditions.

2. Load Capacity and Strength

Metal wheels:Known for their exceptional load-bearing capacity, metal wheels can support very heavy equipment such as cranes, transfer carts, and foundry systems. Their high rigidity ensures minimal deformation under static or dynamic loads.

Polyurethane wheels:While PU wheels cannot match the extreme load capacity of metal wheels, they still offer strong mechanical strength—sufficient for AGVs, forklifts, stackers, conveyors, and factory automation systems. Advanced PU formulas can support several tons while maintaining elasticity and shock absorption.

Summary: If your priority is maximum load capacity, metal wheels are the superior choice. If you need balanced strength with vibration control, PU wheels are ideal.

3. Noise, Vibration, and Floor Protection

Polyurethane wheels absorb vibrations and reduce operational noise significantly. Their softer surface prevents floor damage, making them ideal for smooth indoor flooring, epoxy-coated surfaces, and clean factory environments.

Metal wheels, though extremely durable, generate higher noise levels and can cause floor wear or scratches due to their hardness and lack of cushioning.

Summary: For quiet, smooth operation and floor protection, polyurethane wheels clearly outperform metal wheels.

4. Resistance and Environmental Durability

Metal wheels: Excellent performance under high temperatures, exposure to oil, and heavy impact. However, they can rust or corrode unless coated or treated.

Polyurethane wheels: Highly resistant to chemicals, moisture, and abrasion, and available in anti-static or non-marking types. However, PU can degrade at temperatures above 80–100°C or in continuous high-heat environments.

Summary: Choose metal wheels for high-heat or harsh outdoor conditions, and PU wheels for indoor or chemical-resistant applications.

5. Maintenance and Lifespan

Polyurethane wheels generally require less maintenance, as their soft tread absorbs impacts and protects bearings. However, excessive heat or overloading can shorten their lifespan.Metal wheels have longer structural life, but they may need periodic lubrication and corrosion protection to maintain smooth rolling performance.

Conclusion

Polyurethane wheels and metal wheels each have their strengths — the best choice depends on the application. If you need high load capacity, extreme durability, and heat resistance, metal wheels are the right choice. If you value quiet operation, floor protection, and chemical resistance, polyurethane wheels offer a more versatile and maintenance-friendly option. By understanding these differences, engineers and buyers can select the most efficient, cost-effective wheel type for their specific industrial environment.

Categories

Recent Cases

Recent Products

Recent Blogs

- How Do Polyurethane Wheels Compare To Metal Wheels

- Why Choose Injected Polyurethane (TPU) Wheels for Your Equipment

- Why Roller Coasters Use NDI Polyurethane Wheels

- How to Choose a Poly Wheels Manufacturer That Won't Fail

- Why Polyurethane is the Choice for Pallet Jack and Forklift Wheels

- Pallet Stacker Drive & Idler Wheels for Automated Warehouses

- Mold-on Polyurethane Wheels

- Analysis of the Causes of Cleanroom Stacker Polyurethane Wheel

- Why Are NDI Drive Rollers the Premier Choice for Pallets

- Polyurethane Wheels in Mining

Polyurethane Wheels in Mining

Mold-on Polyurethane Wheels