Durable Drive Load and Steering Wheels for Forklifts

Polyurethane wheels can be used as drive wheels, load-bearing wheels, and steering wheels on forklifts. They have ultra-high load-bearing capacity, are not easy to deform or fall off, are silent and traceless, and have shock absorption properties.

Technical Information

In 24/7 E-commerce warehouses, -25°c cold chain logistics parks, and high-load, 10-ton narrow-aisle warehouses, 80% of forklift downtime is due to wheel failure. Traditional rubber wheels tear easily, nylon wheels are noisy, and steel wheels damage floors. Polyurethane forklift wheels, with their high load capacity, low rolling resistance, cut resistance, and quiet, non-marking properties, have become the preferred choice for warehouse logistics upgrades.

Five core durability requirements for polyurethane forklift wheels

Given the characteristics of warehouse operations characterized by frequent starts and stops, heavy loads, multiple surfaces, and narrow aisles, wheels must meet the following requirements:

1.1 ultra-high load capacity: Designed to handle materials weighing 1-10 tons, these wheels utilize a "high-density material with an embedded steel core" design. The drive wheels can carry 1.5-3 tons each, while the load wheels can carry up to 5 tons. The long-term full-load deformation rate is ≤3%, preventing the forklift from swerving.

1.2 superior wear resistance: Akron abrasion value ≤ 0.15 cm³/1.61 km (2.5 times that of natural rubber), epoxy flooring has a lifespan of 8,000-12,000 hours (3-4 years), reducing replacement frequency by 60%.

1.3 Impact and deformation resistance: With an elastic modulus of 150-200 mpa, it can absorb 75% of instantaneous impacts. It resists cracking and sticking in environments ranging from -20°c (cold chain) to 50°c (open air).

1.4 low rolling resistance + high traction: The rolling resistance coefficient is ≤ 0.03 (40% lower than rubber wheels), increasing the range of electric forklifts by 15-20%. The diamond-patterned design of the drive wheels achieves a friction coefficient of 0.9-1.1, ensuring no slipping on wet surfaces.

1.5 floor protection: Hardness 85-95 shore a adjustable: 85-90 degree soft wheels are suitable for epoxy/pvc floors (pressure ≤ 0.5 mpa, scratch-free); 90-95 degree hard wheels are suitable for concrete floors, offering wear and dust resistance.

Drive/load/steering wheels: Functional segmentation and adaptation

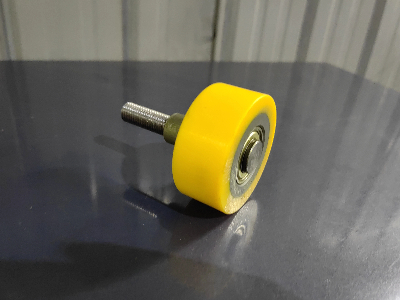

Drive wheel (power core)

The drive wheel is the "power output" of the forklift, converting motor power into traction while also withstanding friction during starting and braking. Its design focuses on power transmission efficiency and durability:

• Structure: "polyurethane outer layer + fiberglass reinforcement + steel core." the wheel width is increased by 20% (e.G., a φ250mm wheel has an 80mm width) to improve traction.

• Applications: E-commerce high-rise forklifts (stable force transmission, reduced motor load), heavy-duty forklifts in the manufacturing industry (resistance to 5-10 tons of impact and uneven wear).

Load wheel (load-bearing core)

Load wheels (also known as load-bearing wheels, often installed below the forks or on either side of the forklift frame) primarily bear the weight of the cargo and the forklift itself. They require no power transmission and are primarily designed for stable load-bearing and low loss.

• Structure: "thick-walled polyurethane + solid steel core." wall thickness increased by 30% (e.G., 25mm for a 200mm diameter wheel). Some wheels are paired side-by-side to distribute the load, and the wheel surface is smooth to reduce wear.

• Applications: Pharmaceutical forklifts (1-2 tons of pharmaceuticals, resistant to pvc scratches), port container forklifts (8-10 tons of cargo, resistant to gravel impact).

Steering wheel (control core)

Steering wheels (mostly installed at the rear of a forklift to control driving direction) must enable tight steering in narrow aisles (minimum turning radius ≤1.5 meters) while also buffering against ground vibrations during steering. Key requirements are flexibility and handling stability.

• Structure: "lightweight polyurethane + universal bearing." wheel weight reduced by 15%. A rounded arc reduces steering resistance, and some wheels have built-in shock-absorbing rubber rings.

• Applications: Narrow-aisle food forklifts (2-meter aisle right-angle turns to prevent beverage spillage), agv forklifts (steering error ≤ 1°, ensuring precise routing).

Polyurethane wheels have been upgraded from general-purpose accessories to specialized functional components. Drive wheels transmit force, load wheels bear load, and steering wheels provide direction control, collectively improving efficiency, reducing costs, and protecting the environment. Future integration of wear monitoring sensors will further support the development of intelligent warehousing.

You have questions, we have answers. Contact us today. Our skilled customer service specialists can help you make the right choice in polyurethane applications.

Polyurethane Wheels for Amusement Rides

Skid Conveyor Rollers