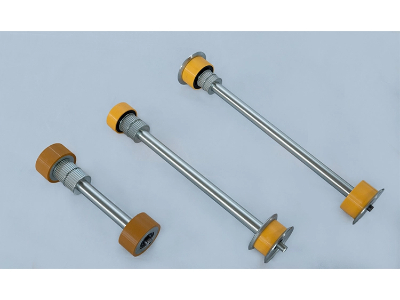

Skid Conveyor Rollers

Slide conveyor rollers feature a steel/iron core and a high-strength polyurethane covering with a hardness of A85–A95 and are widely used in automotive manufacturing, heavy industrial assembly lines, and paint shops.

Technical Information

Skid conveyor rollers feature a steel core and high-strength polyurethane overlay, achieving a hardness of A85–A95 and a thickness of 8–25mm. Each wheel has a load capacity of 500kg to 2 t. These wheels offer high load capacity, wear resistance, noise reduction, and corrosion resistance, making them widely used in automotive manufacturing, heavy industrial assembly lines, and paint shops.

What is a skid conveyor?

A skid conveyor system is a computer-controlled material handling system that utilizes specialized tracks and wheel trains to provide automated, flexible, and precise transport of heavy goods.

Functions of the skid system PU wheel

• Supporting heavy loads – Carrying loads

• Directing – Precise guidance

• Effort saving – Reducing friction

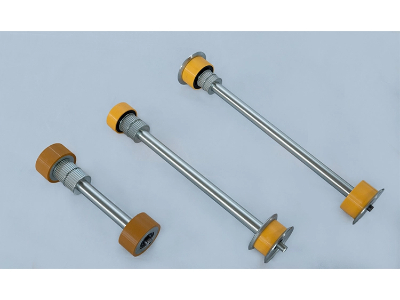

Structural features of skid conveyor wheels

• Wheel structure

The inner wheel core is typically made of steel or cast iron to ensure overall strength.

The outer wheel ring is coated with a highly wear-resistant polyurethane layer for reduced vibration, noise, and protection.

• Bearing Design

Equipped with high-precision deep groove ball bearings or tapered roller bearings, the bearings maintain smooth operation under high loads and continuous operation.

• Mounting Method

Bolt fixing or bearing seat mounting is commonly used, making replacement and maintenance easy.

Polyurethane hardness

• Commonly used Shore A85-A95 or Shore D50-D70 grades, depending on the operating conditions.

• High hardness (A95/D70) → More wear-resistant, suitable for high loads.

• Medium hardness (A85) → Balanced vibration reduction and noise control, suitable for welding and coating lines.

Polyurethane thickness

• Common overmolding thicknesses range from 8mm to 25mm.

• Thicker thickness → Greater elasticity and vibration absorption.

Load capacity

• A single skid pulley can carry 500kg to 2 tons.

• Varies depending on wheel diameter, polyurethane hardness, thickness, and core material.

• Customizable to suit the overall load of the skid conveyor line.

Advantages

• High Load Capacity → The steel core combined with high-strength polyurethane can withstand the weight of large components such as automobile bodies for extended periods.

• Wear-Resistant & Long Life → The polyurethane coating reduces metal friction and extends service life.

• Noise Reduction & Protection → The polyurethane layer absorbs shock and vibration, reduces noise, and protects the workpiece surface.

• Adaptable to Complex Environments → Oil-resistant, corrosion-resistant, and high-temperature resistant (customizable up to 120°C).

• Easy Maintenance → Modular design allows for easy installation and replacement.

Applications

• Automotive Manufacturing

Widely used in skid conveyor systems for welding lines, final assembly lines, and painting lines.

Carrying automobile bodies and complete assemblies.

• Heavy Machinery & Engineering Equipment

Workpiece transport in large equipment and construction machinery production lines.

• Painting & Paint Shops

The polyurethane coating is corrosion-resistant and adaptable to chemicals and high-temperature environments.

• Logistics & Warehousing

For automated handling of pallets, steel structures, and large components.

• Ship & Rail Transit Manufacturing

Handling and assembly lines for large vehicle bodies and ship hull components.

Philson is a manufacturer specializing in the production of polyurethane wheels. We have our own factory, equipment, design, and production staff. For more information, please contact our customer service at sale06@kfqizhongji.com for a quote or more information.

You have questions, we have answers. Contact us today. Our skilled customer service specialists can help you make the right choice in polyurethane applications.

Durable Drive Load and Steering Wheels for Forklifts

Electric Monorail Transport System Wheels