-

WhatsApp: +86 19941574798

WhatsApp: +86 19941574798

-

sale06@kfqizhongji.com

sale06@kfqizhongji.com

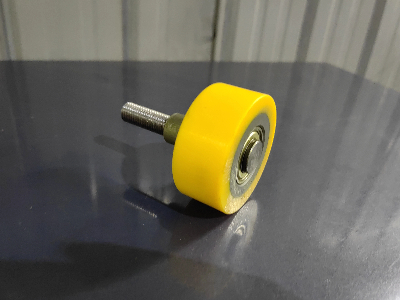

Pallet Stacker Drive & Idler Wheels for Automated Warehouses

Pallet stacker wheels (drive & idler) are critical for AS/RS efficiency. PU material ensures low noise, 5-ton load capacity, and 30-50% longer rail life, enabling millimeter-level precision in automated warehouses and cold storage.

Pallet stacker cranes are automated material handling machines designed for storing and retrieving palletized goods in high - density automated warehouses. They work alongside Warehouse Management Systems (WMS) and conveyor lines to form a seamless automated storage and retrieval system (AS/RS). These cranes can move horizontally along narrow aisles and vertically up tall racks (up to 45 meters high), maximizing vertical storage space while enabling 24/7 operation with millimetre level positioning accuracy. They are widely used in industries such as food, automotive, and pharmaceuticals, including extreme environments like cold storage (-30°C). The stacker crane wheels are the core of the crane’s movement and load - bearing system, determining operational stability, precision, and lifespan. Below is a detailed breakdown of their role, materials, and design, with a focus on wheel specific technologies:

Load Bearing: The wheel assembly, consisting of drive wheels (powered) and idler wheels (load-bearing/guiding), distributes the total weight of the crane and pallets. For example, wheels on double - mast cranes can handle over 5 tons, while those on single - mast models support up to 2 tons.

Guidance & Precision: Wheels work with guide rails to ensure straight - line travel, which is the foundation for the crane’s millimetre - level positioning accuracy during pallet storage/retrieval.

Efficiency & Durability: They reduce friction, enabling smooth starts/stops, cutting energy consumption by 15% - 20%, and minimizing wear on both the wheels and rails, thus extending the overall system’s lifespan.

PU is the most widely used material due to its low noise (≤65 dB), shock absorption, and reduced rail wear (extending rail life by 30%–50%).

In summary, while pallet stacker cranes optimize warehouse efficiency, their wheels are the unsung heroes ensuring reliable, long - term performance. Choosing the right wheel material and design is critical for maximizing uptime and ROI in automated storage systems.

Categories

Recent Cases

Recent Products

Recent Blogs

- How Do Polyurethane Wheels Compare To Metal Wheels

- Why Choose Injected Polyurethane (TPU) Wheels for Your Equipment

- Why Roller Coasters Use NDI Polyurethane Wheels

- How to Choose a Poly Wheels Manufacturer That Won't Fail

- Why Polyurethane is the Choice for Pallet Jack and Forklift Wheels

- Pallet Stacker Drive & Idler Wheels for Automated Warehouses

- Mold-on Polyurethane Wheels

- Analysis of the Causes of Cleanroom Stacker Polyurethane Wheel

- Why Are NDI Drive Rollers the Premier Choice for Pallets

- Polyurethane Wheels in Mining

Mold-on Polyurethane Wheels

Why Roller Coasters Use NDI Polyurethane Wheels