-

WhatsApp: +86 19941574798

WhatsApp: +86 19941574798

-

sale06@kfqizhongji.com

sale06@kfqizhongji.com

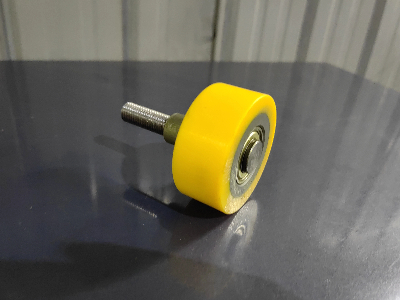

Amusement Equipment Wheels

High-Speed Polyurethane Wheels for Roller Coasters

High-speed polyurethane wheels for roller coasters, including road, side friction, and upstop wheels. Designed for heavy loads, smooth rides, and long-lasting performance in extreme conditions.

High-speed polyurethane wheels for roller coasters, including road, side friction, and upstop wheels. Designed for heavy loads, smooth rides, and long-lasting performance in extreme conditions.

In the world of amusement park engineering, roller coaster performance hinges on the quality and reliability of its wheel system. At the heart of every high-speed, heavy-duty coaster are three critical types of wheels—road wheels, side friction wheels, and upstop wheels—each playing a vital role in ride safety, comfort, and velocity. Polyurethane, known for its exceptional mechanical properties, has become the material of choice for these applications.

Why polyurethane?

Polyurethane offers a unique combination of high load-bearing capacity, wear resistance, impact absorption, and smooth, quiet operation, making it ideal for roller coaster environments. Unlike rubber or steel, polyurethane maintains dimensional stability and grip under high speeds, extreme centrifugal forces, and rapid acceleration/deceleration cycles.

Types of polyurethane coaster wheels

• Road wheels (running wheels)

These wheels carry the full weight of the coaster train. They run directly on the track and are responsible for the smooth, fast movement of the ride. Polyurethane road wheels are engineered to withstand high loads, intense speeds, and continuous use without compromising ride comfort or structural integrity. Their high rebound and low rolling resistance help reduce power consumption and friction-related wear.

• Side friction wheels

Installed vertically alongside the track, side friction wheels control lateral movement during tight turns and banked curves. With polyurethane's excellent abrasion resistance and grip, these wheels maintain train alignment while minimizing vibration and noise—ensuring both ride safety and passenger comfort.

• Upstop wheels (underfriction wheels)

These wheels prevent the train from lifting off the track during inversions or negative g-force moments. Polyurethane upstop wheels must resist tensile stress, shock loading, and shear forces. Their robust yet elastic structure provides secure clamping while extending wheel life in high-intensity coaster applications.

Key advantages of polyurethane coaster wheels

High-speed durability: Optimized for long-term use at speeds exceeding 100 km/h

Heavy load capacity: Handles the mass of full coaster trains and passengers

Vibration and shock absorption: Ensures smoother, quieter rides

Non-marking & track friendly: Protects track surface from excessive wear

Customizable formulations: Tailored hardness, color, and bonding to match specific ride designs

Whether you're designing a new thrill ride or upgrading an existing coaster fleet, choosing high-performance polyurethane wheels for your road, side friction, and upstop systems ensures maximum safety, speed, and spectator satisfaction.

Categories

Recent Cases

Recent Products

Recent Blogs

- How Do Polyurethane Wheels Compare To Metal Wheels

- Why Choose Injected Polyurethane (TPU) Wheels for Your Equipment

- Why Roller Coasters Use NDI Polyurethane Wheels

- How to Choose a Poly Wheels Manufacturer That Won't Fail

- Why Polyurethane is the Choice for Pallet Jack and Forklift Wheels

- Pallet Stacker Drive & Idler Wheels for Automated Warehouses

- Mold-on Polyurethane Wheels

- Analysis of the Causes of Cleanroom Stacker Polyurethane Wheel

- Why Are NDI Drive Rollers the Premier Choice for Pallets

- Polyurethane Wheels in Mining

Polyurethane Wheels for Amusement Equipment in Carousels

none