-

WhatsApp: +86 19941574798

WhatsApp: +86 19941574798

-

sale06@kfqizhongji.com

sale06@kfqizhongji.com

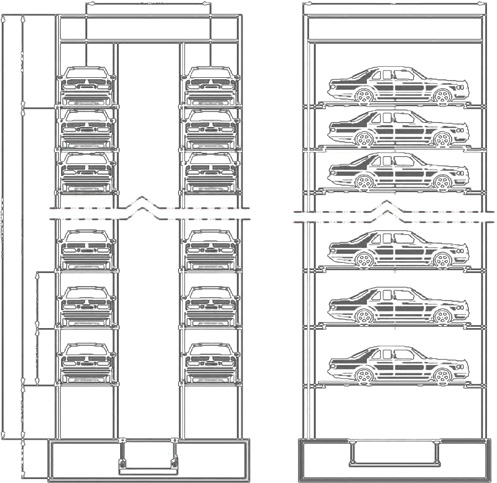

Advantages of Vulkollan Polyurethane Load-Bearing Wheels in Automatic Parking Garages

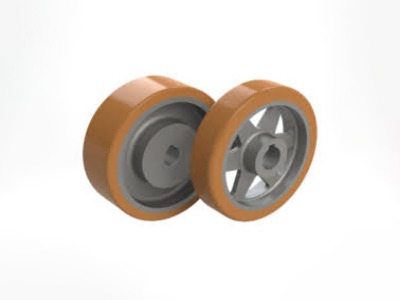

Vulkollan polyurethane load-bearing wheels are typically made of carbon steel, stainless steel, or aluminum alloy as the wheel core and are matched with Vulkollan polyurethane coatings that offer the same performance as NDI.

Vulkollan polyurethane load-bearing wheels are typically made of carbon steel, stainless steel, or aluminum alloy as the wheel core and are matched with Vulkollan polyurethane coatings that offer the same performance as NDI. They are used in automatic parking garages with excellent properties such as good resilience, quiet operation, high load, tear resistance, and friction resistance.

Composition structure of Vulkollan polyurethane load-bearing wheels

Vulkollan polyurethane load-bearing wheels are usually composed of two parts: the wheel core and the polyurethane coating. The structural design takes into account both high load capacity and wear resistance.

• Wheel core material

The wheel core is usually made of high-strength steel or aluminum alloy to ensure the rigidity and impact resistance of the overall structure. Steel wheel cores are suitable for ultra-heavy load environments, while aluminum alloy wheel cores are more advantageous in situations where lightweight requirements are high.

• Polyurethane coating

Vulkollan is a high-performance polyurethane (PU) material with the following characteristics:

High elasticity: It can effectively absorb vibration and reduce operating noise.

Abrasion resistance: It is 3-5 times more wear-resistant than ordinary rubber, extending the service life.

Tear resistance: It is not easy to crack under frequent start-stop and heavy load conditions.

Oil-resistant and chemical-resistant: It is suitable for lubricants, detergents, etc. that may be exposed in garage environments.

Specific application advantages in automatic parking garages

• High load-bearing capacity

The loading plate or handling robot of the automatic parking garage needs to bear several tons of weight. The combination of the high-strength wheel core of the Vulkollan polyurethane load-bearing wheel and the elastic polyurethane coating can provide excellent load distribution capabilities and avoid deformation or damage caused by local stress concentration.

• Low-noise operation

The shock-absorbing properties of polyurethane materials can effectively reduce the noise when the wheels come into contact with the track or the ground, which is particularly suitable for use in places with high requirements for quietness, such as residential or commercial areas.

• Long life and low maintenance

The wear resistance of Vulkollan polyurethane greatly reduces the wear rate of the wheels. Compared with traditional rubber wheels or nylon wheels, the service life can be increased by 2-3 times, reducing the replacement frequency and maintenance costs.

• Anti-skid and precise positioning

Automated parking garages require extremely high vehicle movement accuracy. The high friction coefficient of polyurethane wheels can prevent skidding, ensure that the vehicle loading plate or handling robot runs smoothly on the track, and achieve accurate parking and retrieval.

• Adapt to complex environments

Automated parking garages may face environmental challenges such as temperature changes, humidity, and oil pollution. Vulkollan polyurethane materials have good weather resistance and chemical resistance, ensuring stable performance in the range of -30°C to +80°C.

Vulkollan polyurethane load-bearing wheels have become an ideal choice for automatic parking garage systems due to their high load-bearing, wear-resistant, silent, and long-lasting life. Its optimized structural design (high-strength wheel core + polyurethane coating) not only improves the reliability of equipment operation but also reduces the overall operating costs, providing strong support for modern intelligent parking solutions. If you need to know more information, please feel free to contact us.

Categories

Recent Cases

Recent Products

Recent Blogs

- Why Choose Injected Polyurethane (TPU) Wheels for Your Equipment

- Pallet Stacker Drive & Idler Wheels for Automated Warehouses

- Mold-on Polyurethane Wheels

- Analysis of the Causes of Cleanroom Stacker Polyurethane Wheel

- Why Are NDI Drive Rollers the Premier Choice for Pallets

- Polyurethane Wheels in Mining

- How Do You Maintain Polyurethane Wheel Longevity

- How Do Polyurethane Wheels Compare To Metal Wheels

- What Industries Benefit Most From Using Polyurethane Industrial Wheels

- Polyurethane Forklift Wheels for Warehousing Pallet Handling

Polyurethane Drive Wheel Casting Process Analysis

Polyurethane Forklift Wheels for Warehousing Pallet Handling