-

WhatsApp: +86 19941574798

WhatsApp: +86 19941574798

-

sale06@kfqizhongji.com

sale06@kfqizhongji.com

Why Choose Injected Polyurethane (TPU) Wheels for Your Equipment

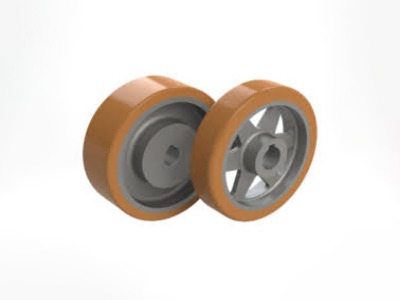

Injected Polyurethane Wheels (often referred to as TPU wheels or Thermoplastic Polyurethane wheels) are manufactured using a high-pressure injection molding process.

Injected Polyurethane Wheels (often referred to as TPU wheels or Thermoplastic Polyurethane wheels) are manufactured using a high-pressure injection molding process. Unlike traditional cast polyurethane, which is poured into open molds and cured, injected polyurethane typically starts as pellets. These pellets are melted down and injected into a precision mold, often directly around a wheel core made of nylon, polypropylene, or metal.

This manufacturing technique results in a wheel that offers the elasticity of rubber combined with the toughness and durability of metal or hard plastics.

Key Benefits of Injected Polyurethane Wheels

Why should you choose this specific type of wheel for your equipment? Here are the primary advantages:

1. Superior Floor Protection

One of the most significant selling points of Injected Polyurethane Wheels is their ability to protect flooring. They are non-marking, meaning they won't leave unsightly black scuffs on epoxy, tile, or hardwood floors. This makes them ideal for environments where cleanliness and aesthetics are priorities, such as hospitals, schools, and retail stores.

2. Smooth and Quiet Operation

Noise pollution is a real concern in modern workplaces. These wheels offer excellent noise reduction compared to harder materials like steel or nylon. The polyurethane tread absorbs vibrations and shocks from uneven surfaces, ensuring a silent and smooth glide that improves user comfort.

3. Resistance to Chemicals and Abrasion

Injected Polyurethane Wheels are chemically resistant to oils, greases, solvents, and cleaning agents. This makes them a durable choice for automotive garages, laboratories, and food processing plants where exposure to harsh substances is frequent. Furthermore, they are highly resistant to abrasion, ensuring a long service life even on rough concrete.

4. Lightweight Construction

Because the injection process often utilizes high-strength nylon or polypropylene cores, these wheels are significantly lighter than their cast iron or steel counterparts. This reduces the overall weight of the cart or trolley, making it easier for personnel to maneuver manual equipment and reducing fatigue.

Injected vs. Cast Polyurethane: Which Do You Need?

It is important to distinguish between Injected Polyurethane Wheels and Cast Polyurethane Wheels.

Choose Injected Polyurethane for dynamic applications, lighter to medium-duty loads, high-volume requirements, and environments where budget and smooth mobility are key.

Choose Cast Polyurethane if you are dealing with extreme heavy-duty loads (thousands of pounds per wheel) or high-speed towing applications where heat build-up is a major factor.

Conclusion

If you are looking for a wheel solution that offers the perfect "middle ground" between soft rubber and hard plastic, Injected Polyurethane Wheels are the answer. They provide the durability needed for industrial environments while maintaining the floor protection and quiet operation required in commercial spaces. By investing in high-quality injected polyurethane, you ensure longer equipment life, reduced maintenance costs, and a better experience for your operators.

Categories

Recent Cases

Recent Products

Recent Blogs

- Why Choose Injected Polyurethane (TPU) Wheels for Your Equipment

- Pallet Stacker Drive & Idler Wheels for Automated Warehouses

- Mold-on Polyurethane Wheels

- Analysis of the Causes of Cleanroom Stacker Polyurethane Wheel

- Why Are NDI Drive Rollers the Premier Choice for Pallets

- Polyurethane Wheels in Mining

- How Do You Maintain Polyurethane Wheel Longevity

- How Do Polyurethane Wheels Compare To Metal Wheels

- What Industries Benefit Most From Using Polyurethane Industrial Wheels

- Polyurethane Forklift Wheels for Warehousing Pallet Handling

Pallet Stacker Drive & Idler Wheels for Automated Warehouses

none