-

WhatsApp: +86 19941574798

WhatsApp: +86 19941574798

-

sale06@kfqizhongji.com

sale06@kfqizhongji.com

High Quality Polyurethane Wheels Service Provider

Casting Process

The polyurethane wheel production process involves customized molds, bubble-free casting, curing, and finishing, resulting in a wheel body that is strong, load-bearing, and anti-debonding.

Economic Cost

Philson uses high-quality raw materials, thoughtful design and precision processing to provide cost-effective products and reduce the possibility of damage and maintenance.

Complete Equipment

Philson has a variety of equipment including polyurethane casting machine, precision machining, wheel hub testing, and processing to ensure the quality of the wheel hub.

One-Stop Service

We provide 24/7 services before, during, and after sales. You can contact customer service to customize wheels with or without drawings.

Skills & FAQ

Suitable Scenarios, Advantages & Customization of Polyurethane-Coated Wheels

Which scenarios/equipment are your polyurethane-coated wheels suitable for?

Our polyurethane-coated wheels have a wide range of applicable scenarios and equipment, including Warehouse Automation and Logistics (Automated Guided Vehicle (AGV), Automated Mobile Robot (AMR)、Rail Guided Vehicle(RGV)、Laser-Guided Vehicle (LGV)、Autonomous Intelligent Vehicle (AIV), Self-Guided Vehicle (SGV)), Automated Conveyor Lines, Pharmaceutical and Chemical Industries, Food-grade Processing Equipment, Cold Chain Transportation, Automobile Manufacturing, Electronics and Electrical Appliances, etc. They are compatible with any rolling scenario requiring wear resistance, noise reduction, and load-bearing capacity, and can also be customized according to special equipment dimensions.

What are the advantages of polyurethane-coated wheels compared to rubber wheels and metal wheels?

Compared with rubber wheels and metal wheels, polyurethane-coated wheels have three core advantages: 1. Superior wear resistance and durability, with a service life 3-5 times that of ordinary rubber wheels, and not easy to age or crack; 2. Balanced performance, combining noise reduction and shock absorption, anti-slip grip, and corrosion resistance, suitable for complex working conditions; 3. Higher load-bearing capacity, outperforming rubber wheels of the same size, and no damage to the ground.

Do you support customization of non-standard polyurethane-coated wheels? What parameters are required?

We fully support the customization of non-standard polyurethane-coated wheels to meet the personalized needs of different equipment and special working conditions. The following key parameters are required for customization: wheel diameter, wheel width, shaft hole size, rated load capacity, operating environment temperature, special material requirements such as oil resistance or acid and alkali resistance, and equipment operating speed. Specific details can be adjusted through negotiation based on the complexity of the customization.

Philson provides high-quality polyurethane wheels for various scenarios.

Recommended Products

Philson provides polyurethane/nylon products, including various wheels, plates, and non-standard customized products.

10+

High-performance mature formulas

Fully automatic production lines

600,000

PU wheels a year

7-10

years product design life

Recommended Application

Polyurethane-coated wheels are used in semiconductor workshop equipment, amusement equipment, material handling equipment.

Electrical Monorail System (EMS) Polyurethane Friction Drive Wheel

Special Equipment

Electrical Monorail System (EMS) Polyurethane Friction Drive Wheel

Special Equipment

Polyurethane Wheels for Stacker Crane Boxes AS/RS

Material Handling Drive System

Polyurethane Wheels for Stacker Crane Boxes AS/RS

Material Handling Drive System

93A Polyurethane Wheels for Heavy-Duty Metal Transportation

Heavy Machinery

93A Polyurethane Wheels for Heavy-Duty Metal Transportation

Heavy Machinery

Polyurethane Wheels Elevate Amusement Ride Performance

Amusement Equipment Wheels

Polyurethane Wheels Elevate Amusement Ride Performance

Amusement Equipment Wheels

Polyurethane Guide Wheel on Drop Tower Ride

Amusement Equipment Wheels

Polyurethane Guide Wheel on Drop Tower Ride

Amusement Equipment Wheels

High-Speed Polyurethane Wheels for Roller Coasters

Amusement Equipment Wheels

High-Speed Polyurethane Wheels for Roller Coasters

Amusement Equipment Wheels

Recommended Blog

The Technical Analysis and Industrial Trends of Polyurethane Heavy Duty Drive Wheels

Why Choose Injected Polyurethane (TPU) Wheels for Your Equipment

Injected Polyurethane Wheels (often referred to as TPU wheels or Thermoplastic Polyurethane wheels) are manufactured using a high-pressure injection molding process.

Pallet Stacker Drive & Idler Wheels for Automated Warehouses

Pallet stacker wheels (drive & idler) are critical for AS/RS efficiency. PU material ensures low noise, 5-ton load capacity, and 30-50% longer rail life, enabling millimeter-level precision in automated warehouses and cold storage.

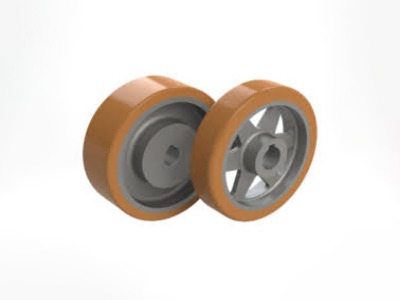

Mold-on Polyurethane Wheels

Mold-on polyurethane wheels are industrial wheels manufactured by firmly bonding polyurethane material to a metal or plastic core via a molding process.