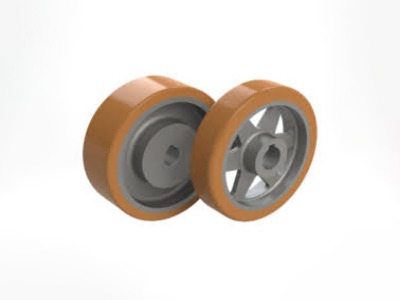

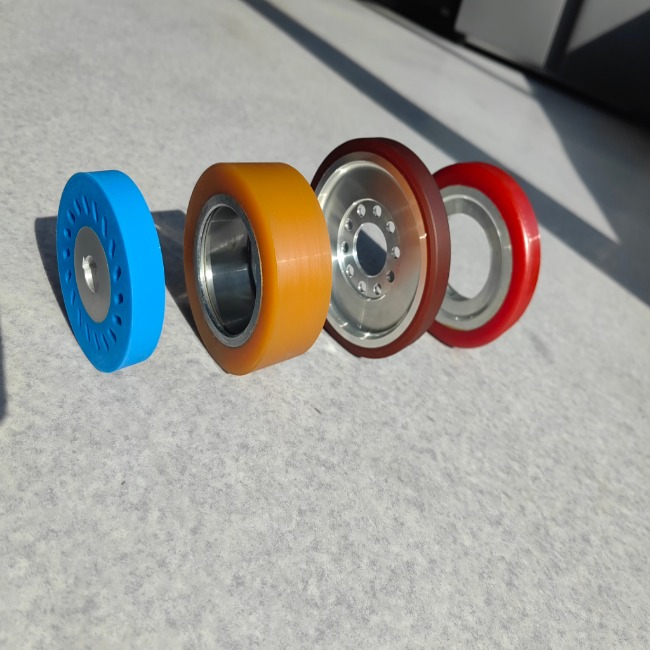

Industrial Polyurethane‑Tyred Iron Centred Wheels

Polyurethane‑tyred wheels deliver high abrasion resistance, superior load capacity, low noise and floor protection. Selection, specs and maintenance tips.

Technical Information

Industrial polyurethane‑tyred wheels are widely used across material‑handling, logistics, manufacturing and heavy industry because they combine excellent load capacity, abrasion resistance and ride quality with long service life. Below is a practical technical overview to help you understand performance, construction, selection and maintenance.

What is a polyurethane‑tyred (PU‑tyred) wheel? - A PU‑tyred wheel consists of a metal core with a polyurethane tread bonded or cast around it. The tyre can be applied by casting in place, vulcanization, or adhesive bonding.

Why use Polyurethane for Heavy‑duty Wheels?

1. Abrasion resistance: PU outlasts natural rubber and many plastics in abrasive environments.

2. Load capacity and resilience: Polyurethane supports high static and dynamic loads with lower deformation than rubber at comparable hardness.

3. Shock and noise reduction: Effective vibration damping and quieter operation than metal or nylon cores.

4. Floor protection & traction: PU treads reduce floor damage and provide good traction without marking (depending on formulation).

5. Chemical and heat resistance: Tailorable formulations resist oils, greases and some chemicals; high‑temperature grades are available.

Typical Properties and Specs

Hardness: commonly 70A–95A Shore (softer for ride/floor protection, harder for abrasion and heavy loads). Choose hardness to balance floor protection versus load/abrasion needs.

1. Density: ~1.1–1.3 g/cm³ (varies by formulation).

2. Temperature range: standard −20°C to +80°C; specialized grades up to ~120°C.

3. Tensile/tear: varies by compound; heavy‑duty grades optimized for high tear strength and low abrasion.

4. Load capacity: highly dependent on wheel diameter, tread width, hardness and design—industrial units range from a few hundred kilograms to several tonnes per wheel. Consult manufacturer load charts.

Conclusion and Recommendation

For heavy‑duty industrial applications where abrasion resistance, load capacity, noise reduction and floor protection are required, polyurethane‑tyred wheels, especially polyurethane bonded to cast‑iron cores, are an excellent choice. Specify wheel diameter, tread width and hardness based on load and floor conditions; insist on proper surface prep and an adhesion‑proven bonding system from the manufacturer. Regular inspections and maintenance will maximize service life and safety.

You have questions, we have answers. Contact us today. Our skilled customer service specialists can help you make the right choice in polyurethane applications.

Polyurethane Tread on Steel Keyed Drive Wheels

Industrial Polyurethane Elastomer Wheels