-

WhatsApp: +86 19941574798

WhatsApp: +86 19941574798

-

sale06@kfqizhongji.com

sale06@kfqizhongji.com

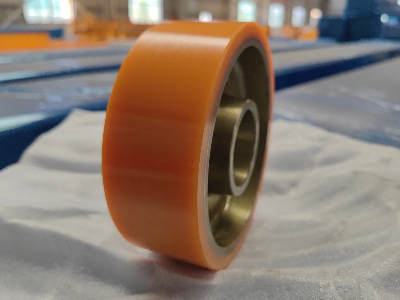

Why Are NDI Drive Rollers the Premier Choice for Pallets

NDI drive rollers are widely used in warehousing, manufacturing, logistics, and other applications due to their exceptional wear and tear resistance, low drag, and low heat buildup.

NDI drive rollers are widely used in warehousing, manufacturing, logistics, and other applications due to their exceptional wear and tear resistance, low drag, and low heat buildup.

Understanding NDI Material: A High-Performance Engineering Plastic That "Changes Color"

NDI is a premium thermoplastic polyimide material. One of its most intuitive and unique features is its variable color. The color of NDI components changes over time and temperature during storage and use, typically appearing as follows:

• New/New: Creamy white or light yellow.

• Initial use: Gradually changes to light brown.

• After extended use: Further deepens to dark brown, eventually approaching black.

This color change is not a quality defect, but rather a manifestation of the natural crystallization of the NDI material's molecular structure under heat and stress. It is an outward sign of its high-performance characteristics and does not affect its mechanical properties.

The Core Advantages of NDI Material: Why is it so suitable for drive wheels?

The drive wheel is the power output of a pallet truck. It simultaneously performs multiple challenging tasks: carrying the weight of the truck and cargo (both static and dynamic), providing traction and drive torque, and ensuring steering and maneuverability. This requires the drive wheel material to possess exceptionally high comprehensive performance.

Excellent Mechanical Properties

• High Tensile and Tear Strength: NDI's exceptionally strong molecular structure provides exceptional mechanical strength, ensuring the drive wheel resists breakage or damage under heavy loads and impact, providing robust load-bearing capacity.

• Low Compression Set: Under prolonged and heavy loads, NDI wheels maintain their original shape and size without plastic dents, ensuring a stable contact patch and driving efficiency.

• High Wear Resistance: This significantly extends the life of the roller, reducing the hassle and cost of frequent replacement due to wear.

Excellent Dynamic Performance

• High Resilience: NDI material exhibits excellent rebound properties, effectively cushioning shock and vibration, protecting the pallet truck's internal transmission mechanisms.

• Low Heat Generation: During high-speed, high-frequency driving and steering, internal energy loss and heat accumulation are minimized, preventing the risk of material softening, performance degradation, or even tire blowouts caused by high temperatures.

Unique Microporous Structure

• High Volume Compressibility: The microporous structure gives the NDI pallet wheel excellent elasticity and shock absorption, allowing it to easily navigate gaps and small obstacles.

• Minimal Lateral Expansion: Even under high compression pressure, lateral expansion is minimal, ensuring sufficient clearance between the wheel and the vehicle body and preventing friction and seizure.

Excellent Environmental Resistance

• Heat Resistance: Continuous operating temperatures reach 80°C, with short-term temperature resistance up to 120°C, far exceeding that of ordinary polyurethane (PU) materials, making it ideal for high-intensity operating environments.

• Media Resistance: Excellent resistance to grease, oil, ozone, and UV rays, enabling it to withstand a variety of complex environments such as warehouses and workshops, delaying aging.

Philson Services

• Precision Customization: Philson can precisely customize pallet drive rollers based on your specific operating conditions, equipment model, and special requirements (such as varying hardness, size, and structure), ensuring a perfect fit and optimized performance.

• Wheel Refurbishment Service: To help customers reduce costs and promote environmental protection, Philson offers a professional wheel refurbishment service. If your old wheels still have intact metal rims, simply send them back and Philson will re-cover them with high-performance NDI polyurethane, ensuring like-new performance at a fraction of the cost of a new assembly.

• Professional Consultation: Before purchasing, consult with Philson's technical team, who can provide recommendations on the most suitable material (NDI or other) and solutions.

Categories

Recent Cases

Recent Products

Recent Blogs

- How Do Polyurethane Wheels Compare To Metal Wheels

- Why Choose Injected Polyurethane (TPU) Wheels for Your Equipment

- Why Roller Coasters Use NDI Polyurethane Wheels

- How to Choose a Poly Wheels Manufacturer That Won't Fail

- Why Polyurethane is the Choice for Pallet Jack and Forklift Wheels

- Pallet Stacker Drive & Idler Wheels for Automated Warehouses

- Mold-on Polyurethane Wheels

- Analysis of the Causes of Cleanroom Stacker Polyurethane Wheel

- Why Are NDI Drive Rollers the Premier Choice for Pallets

- Polyurethane Wheels in Mining

High-Quality Polyurethane Fork Wheels from China Manufacturer

Mold-on Polyurethane Wheels