-

WhatsApp: +86 19941574798

WhatsApp: +86 19941574798

-

sale06@kfqizhongji.com

sale06@kfqizhongji.com

Why Roller Coasters Use NDI Polyurethane Wheels

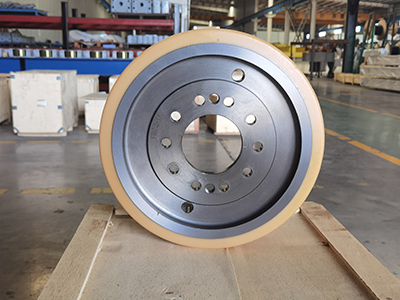

Roller coaster wheels are made of NDI-based polyurethane (Vulkollan®), featuring low hysteresis, Shore A hardness, and heat dissipation prevent wheels from melting at high speeds.

Roller coaster wheels are not made of standard "off-the-shelf" polyurethane. Because coasters generate immense heat through friction and undergo extreme "G-loads," they require high-performance, hot-cast elastomers.

The industry standard for these wheels is NDI-based polyurethane, most famously known by the brand name Vulkollan®.

1. The Chemistry: Why NDI?

Most industrial polyurethanes use MDI or TDI as their base chemical (isocyanate).3 However, roller coasters move so fast that the internal friction within the wheel creates massive heat.

NDI (1.5-Naphthalene Diisocyanate): This is the "secret sauce." It has a rigid, symmetrical molecular structure that allows the wheel to flex and return to its original shape with very little internal heat buildup (low hysteresis).

Vulkollan®: Developed by Covestro (formerly Bayer), this is the specific NDI-based material used by almost all major ride manufacturers (B&M, Intamin, Mack Rides).

2. Key Properties

Manufacturers choose specific formulations based on the "Shore Hardness" (measured on the Shore A scale) and environmental factors:

Property | Why it Matters for Coasters |

High Dynamic Load | Supports the weight of the train during high-G turns without deforming. |

Low Rolling Resistance | Keeps the train moving fast and prevents it from "stalling" before the end of the track. |

Heat Dissipation | Prevents the wheel from melting or "chunking" (breaking apart) during a long day of operation. |

Flat-Spot Resistance | Prevents the wheel from developing a flat side when the train sits in the station for a few minutes. |

3. Specialty Variations

Depending on where the wheel is located on the train, parks use different types of polyurethane:

Road Wheels (Top): Usually the hardest polyurethane (around 90–95 Shore A) to handle the weight and speed.

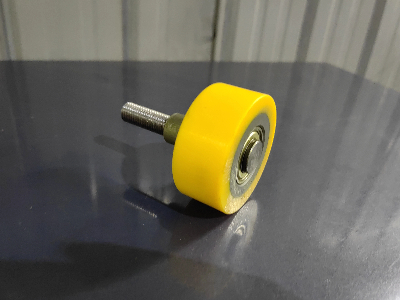

Guide & Up-Stop Wheels (Side/Bottom): These might be slightly softer to provide a "grip" on the track or dampen vibrations, improving ride comfort.

Specialty Grades: Brands like Vulkodyn® are specifically engineered for "Hypercoasters" and "Giga-coasters" that reach speeds over 70–90 mph, where standard Vulkollan might still overheat.

4. Why not use Rubber or Nylon?

Rubber: Too soft; it would generate too much friction, slow the ride down significantly, and shred under high speeds.

Nylon/Hard Plastic: Too hard; it would be incredibly loud and transmit every tiny bump on the track to the passengers, making the ride feel "rattly."

Categories

Recent Cases

Recent Products

Recent Blogs

- How Do Polyurethane Wheels Compare To Metal Wheels

- Why Choose Injected Polyurethane (TPU) Wheels for Your Equipment

- Why Roller Coasters Use NDI Polyurethane Wheels

- How to Choose a Poly Wheels Manufacturer That Won't Fail

- Why Polyurethane is the Choice for Pallet Jack and Forklift Wheels

- Pallet Stacker Drive & Idler Wheels for Automated Warehouses

- Mold-on Polyurethane Wheels

- Analysis of the Causes of Cleanroom Stacker Polyurethane Wheel

- Why Are NDI Drive Rollers the Premier Choice for Pallets

- Polyurethane Wheels in Mining

How to Choose a Poly Wheels Manufacturer That Won't Fail

none