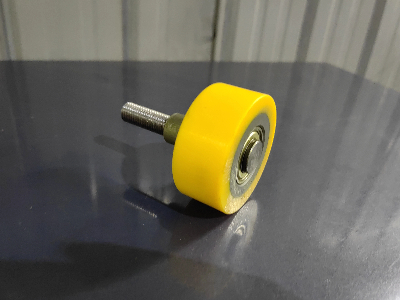

Industrial Polyurethane Elastomer Wheels

Polyurethane (PU) elastomer wheels, with their unique physical properties positioned between rigid plastics and soft rubber, have become the premier choice for high-performance mobility mechanisms.

Technical Information

Polyurethane (PU) elastomer wheels, with their unique physical properties positioned between rigid plastics and soft rubber, have become the premier choice for high-performance mobility mechanisms.

I. Dynamic Mechanical Properties: The Physical Advantages of Polyurethane

The core competitiveness of polyurethane wheels stems from the molecular structure of their multi-phase block copolymers. This structure consists of hard segments that provide mechanical strength and soft segments that grant elasticity.

1. Superior Load Density and Compression Resistance

Compared to natural rubber, polyurethane possesses a significantly higher Young's Modulus. Under identical deformation levels, PU can support loads several times greater than rubber. Furthermore, high-quality polyurethane features extremely low Compression Set. Even under long-term static rated loads, the tread is resistant to developing flat spots, ensuring smoothness during initial startup.

2. Dynamic Heat Generation and Hysteresis Loss

For electric forklifts or AGVs (Automated Guided Vehicles), Hysteresis Loss is a critical metric. Polyurethane minimizes energy loss during cyclic compression, which translates to:

Low Rolling Resistance: Significantly reduces battery consumption and extends operational uptime.

Temperature Control: Minimizes internal heat buildup, preventing debonding between the PU tire and the wheel core caused by thermal accumulation.

II. Analysis of Core Technical Indicators

When evaluating a professional-grade polyurethane wheel, the following key performance parameters must be scrutinized:

1. Abrasion Resistance

Using Akron or DIN abrasion testing, the wear index of polyurethane is typically only 1/3 to 1/5 that of rubber. In environments with rough concrete floors or high-frequency operation, this equates to longer replacement cycles and lower maintenance costs.

2. Bonding Strength

The failure of a polyurethane wheel often occurs not from material wear, but from delamination (debonding). Professional-grade manufacturing employs multi-stage chemical cleaning and specialized primers to ensure the peel strength between the PU and the core (iron or aluminum) exceeds the tear strength of the polyurethane itself, allowing it to withstand high shear forces under heavy loads.

3. Hardness Gradient and Friction Coefficient

Industrial applications typically utilize a hardness range of 90A to 95A, achieving an optimal balance between traction and rolling resistance.

High Traction: Provides excellent grip, preventing slippage even on damp or smooth surfaces.

Acoustic Damping: Natural damping properties provide vibration reduction, resulting in operational noise levels far lower than those of nylon wheels.

III. Chemical and Environmental Adaptability in Extreme Conditions

Oil and Chemical Resistance: Polyurethane exhibits exceptional resistance to mineral oils, greases, and most non-polar solvents, making it ideal for machining workshops.

Hydrolysis Resistance: In high-temperature and high-humidity environments, standard polyurethane is prone to hydrolysis. Professional-grade products utilize Polyether-based polyurethane to ensure mechanical properties do not degrade in humid climates or cold-chain environments.

Microbial Resistance: In the food and medical industries, polyurethane materials demonstrate excellent antimicrobial properties, meeting stringent hygiene audit standards.

IV. Industry Applications and Selection Guide

Application | Key Focus | Recommended Solution |

AGV / AMR Robotics | Frictional stability, high positioning accuracy | High-rebound PU with resilience > 60% |

Heavy-Duty Automated Warehousing | Dynamic loads, compressive strength | Large-diameter aluminum core PU wheels for enhanced heat dissipation |

Medical Equipment | Ultra-quiet operation, Non-marking | Soft PU (75A-85A) to ensure zero floor scarring |

V. Conclusion

A polyurethane wheel is not a simple consumable but a product of precision engineering. By optimizing prepolymer formulations, enhancing chemical bonding processes, and precisely controlling hardness, these components significantly improve the operational reliability of industrial equipment while reducing total cost of ownership (TCO). Ready to Reduce Your Operational Costs and Downtime? Switch to our high-performance PU wheels and experience up to a 3x longer service life compared to standard alternatives. Let us help you calculate your potential savings and optimize your fleet's performance.

You have questions, we have answers. Contact us today. Our skilled customer service specialists can help you make the right choice in polyurethane applications.

Flame Retardant Polyurethane Wheels

Industrial 200mm (8-inch) Polyurethane Wheels