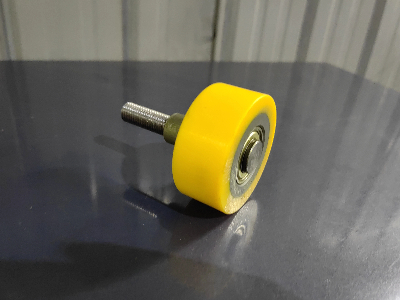

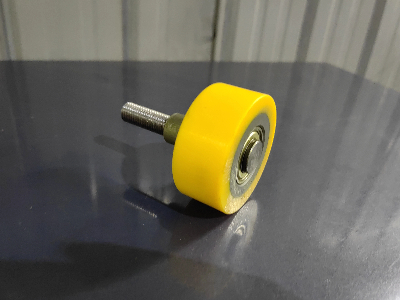

Reliable Stacker Guide Wheels for Demanding Environments.

Philson polyurethane stacker guide wheels are designed for automated warehouses, delivering exceptional stability, low-noise operation, and high wear resistance.

Technical Information

In automated warehouses and logistics systems, stacker cranes are core equipment for efficient storage and retrieval. Their smooth and precise operation relies on high-performance polyurethane guide wheels, ensuring the stacker follows its intended path accurately.

Structure and Working Principle of Stacker Guide Wheels

The guide wheels are secured to the stacker’s travel mechanism via nuts. They work in coordination with the travel wheel box or polyurethane drive wheels, rolling along the track to provide fundamental support for core functions.

Dual-Sided Guidance Design: Guide wheels positioned on both sides of the track effectively prevent the stacker from deviating during high-speed or high-load operation, ensuring precise alignment.

Broad Track Adaptability: Whether for ground tracks or elevated guide rails, Philson guide wheels offer full compatibility to meet the flexible needs of various warehouse layouts.

Core Advantages of Polyurethane Materials

The polyurethane materials used by Philson achieve an ideal balance between performance and durability.

Low Heat Generation: Suitable for high-frequency operation, preventing premature wear due to overheating.

Ultra-Quiet Running: Significantly reduces noise pollution in automated warehouses and cleanroom environments.

High Resilience and Instant Rebound: Maintains excellent stability and shock absorption during load handling.

Superior Wear and Tear Resistance: Ensures long service life even under continuous heavy-duty conditions.

Balanced Hardness: Combines support strength with cushioning, effectively protecting both equipment and floors.

Customized Solutions for Various Industrial Scenarios

Philson offers comprehensive customization to meet diverse industrial application needs:

Cleanrooms/Food & Pharmaceutical Industries: Stainless steel wheel cores with anti-static properties to meet dust-free and hygienic standards.

Heavy-Duty Logistics Scenarios: Cast steel or forged steel wheel cores designed specifically for high-intensity, high-load applications.

Extreme Temperature Environments: Special high-temperature or low-temperature resistant polyurethane compounds suitable for cold storage, metallurgical plants, or high-temperature workshops.

Durability Assurance: Special surface treatment processes prevent debonding and deformation, backed by a one-year quality guarantee.

Main Application Areas

Philson guide wheels are widely used in the following scenarios:

Automated Storage and Retrieval Systems (AS/RS)

High-bay warehouses equipped with stacker cranes

Logistics handling and sorting platforms

Cold storage and food-grade material handling systems

Conclusion

Philson's Stacker Guide Wheels combine advanced material performance with in-depth customizable design, ensuring your stacker operates with stability, precision, and longevity in any industrial environment. Contact us today for a professional custom solution.

You have questions, we have answers. Contact us today. Our skilled customer service specialists can help you make the right choice in polyurethane applications.

Pallet Rollers for Industrial Trucks

PU Wheels and Casters for Aviation and Aerospace