PU Wheels and Casters for Aviation and Aerospace

Polyurethane (PU) wheels and casters are widely applied in aircraft maintenance platforms, tool carts, towable ground support equipment (GSE), cargo trolleys, cleanroom handling systems, and assembly line transport vehicles.

Technical Information

In the aviation and aerospace industry, ground support and component handling demand equipment that meets strict engineering standards. Polyurethane (PU) wheels and casters are widely applied in aircraft maintenance platforms, tool carts, towable ground support equipment (GSE), cargo trolleys, cleanroom handling systems, and assembly line transport vehicles. Their reliability directly impacts efficiency, safety, and protection of high-value aerospace assets.

Application requirements in aerospace

Wheels used in aerospace facilities are exposed to unique operating conditions. Unlike conventional industrial environments, aerospace applications demand:

• High load capacity – wheels must carry concentrated loads of heavy equipment and aircraft components, often exceeding several tons per vehicle.

• Dimensional stability – minimal deformation under long-term static loads, essential for storage carts and aircraft tooling systems.

• Fuel and chemical resistance – exposure to aviation fuels, hydraulic oils, cleaning solvents, and de-icing fluids requires superior chemical resistance.

• Low rolling resistance – energy-efficient movement of heavy loads reduces operator fatigue and ensures precise positioning of equipment.

• Wide temperature tolerance – PU wheels must maintain performance from -40°c on airfields to +80°c in indoor maintenance hangars.

• Anti-static and cleanroom compliance – for precision aerospace component handling, wheels must meet electrostatic discharge (ESD) requirements and ensure low particle emission.

• Impact and wear resistance – repeated shock loading from tow tractors, uneven ground surfaces, and frequent maneuvering requires exceptional durability.

Polyurethane performance advantages

High-performance PU formulations provide:

• Tensile strength: Up to 50 MPa for heavy-duty load support.

• Shore hardness range: A85–D75, customizable for shock absorption or rigidity.

• Abrasion loss: <50 mm³ (DIN 53516 standard), ensuring long service life.

• Compression set resistance: Minimizes flat-spotting under static loads.

• Low noise operation: Critical for hangar and testing environments.

Philson’s manufacturing capabilities

Philson specializes in engineering-grade polyurethane wheels tailored for aviation and aerospace applications. Our strengths include:

• In-house design and r&d team – engineers capable of designing wheels to meet aerospace ground support standards.

• Advanced manufacturing facilities – precision CNC machining, high-pressure casting systems, and automated molding ensure dimensional accuracy.

• Comprehensive testing – load capacity, chemical resistance, hardness, tensile strength, and rolling resistance are verified using sophisticated equipment.

• Premium raw materials – imported prepolymers and curatives with consistent molecular structures guarantee stable performance.

• Over 10 years of expertise – accumulated knowledge in heavy-duty wheel design and polyurethane chemistry.

• Efficient supply chain – competitive pricing and short lead times without compromising quality.

Polyurethane wheels and casters are indispensable for aerospace ground operations and precision equipment handling. With superior load capacity, chemical resistance, and dimensional stability, they ensure reliability in the most demanding conditions. Philson combines advanced materials, engineering expertise, and strict quality control to deliver aerospace-grade PU wheels that meet international standards and exceed industry expectations.

You have questions, we have answers. Contact us today. Our skilled customer service specialists can help you make the right choice in polyurethane applications.

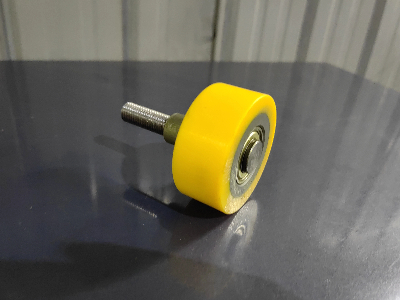

Reliable Stacker Guide Wheels for Demanding Environments.

Polyurethane Wheel Relining for Cost-Effective Industrial Performance