-

WhatsApp: +86 19941574798

WhatsApp: +86 19941574798

-

sale06@kfqizhongji.com

sale06@kfqizhongji.com

Heavy Machinery

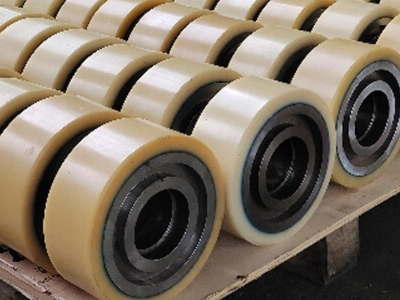

PU Load Wheels for Tunnel Boring Machines

Durable polyurethane load wheels for tunnel boring machines, ideal for cement segment transport. High load capacity, wear resistance, and customizable for harsh environments.

Durable polyurethane load wheels for tunnel boring machines, ideal for cement segment transport. High load capacity, wear resistance, and customizable for harsh environments.

What is a polyurethane load wheel?

A polyurethane load wheel for tunnel boring machines is a wheel constructed with a polyurethane tread bonded to a steel or cast iron core. These wheels are designed to carry extreme loads, resist abrasion, and provide consistent performance in abrasive and high-humidity tunnel conditions. Commonly known as wheels for cement segment transport, they are also used on TBM segment carriers, backup systems, and segment feeder vehicles.

Key benefits of polyurethane wheels for TBMs

• High load-bearing strength

Polyurethane’s excellent compression properties make it ideal for supporting the heavy static and dynamic loads of TBMs and precast concrete tunnel segments.

• Abrasion and cut resistance

The polyurethane tread resists wear caused by rock dust, moisture, and sharp debris, ensuring a longer service life even under continuous operation.

• Shock absorption and noise reduction

These wheels absorb vibrations during segment movement, reducing damage to transported segments and minimizing operating noise, which is essential in confined tunnel spaces.

• Non-marking surface

Polyurethane wheels do not damage or stain concrete surfaces, making them ideal for handling cement segments and transporting tunnel linings.

• Customizable to application needs

Wheels can be designed to specific diameters, load capacities, durometer hardness, and mounting configurations to match unique TBM system requirements.

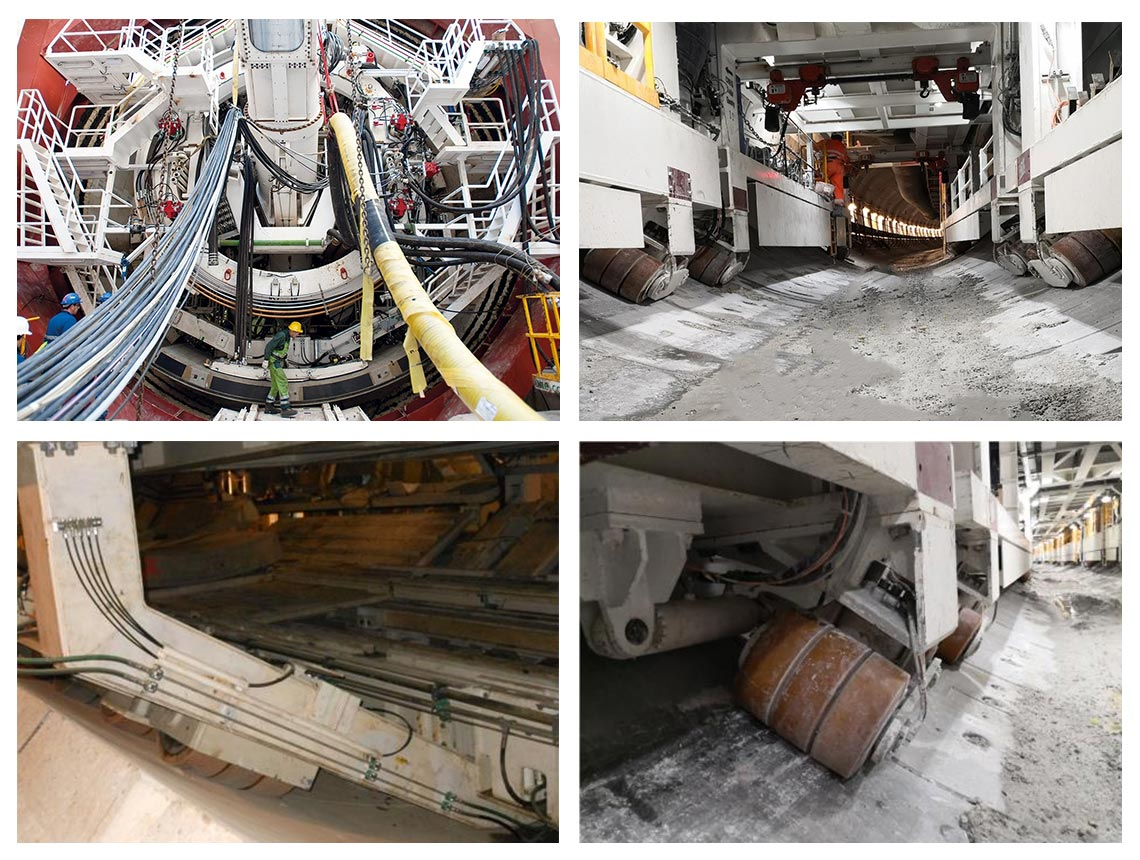

Application areas

• Tunnel boring machine support systems

• Cement segment transport trolleys

• TBMs' backup gantries and trailers

• Segment feeder systems for continuous lining installation

These wheels are engineered to perform in confined, rugged, and high-dust environments where traditional wheels may fail.

Polyurethane wheels for tunnel boring machines provide the ideal combination of strength, durability, and customization. Whether moving the TBM itself or transporting cement segments during tunnel lining installation, these load wheels deliver exceptional performance and minimal maintenance in harsh underground environments.

Categories

Recent Cases

Recent Products

Recent Blogs

- How Do Polyurethane Wheels Compare To Metal Wheels

- Why Choose Injected Polyurethane (TPU) Wheels for Your Equipment

- Why Roller Coasters Use NDI Polyurethane Wheels

- How to Choose a Poly Wheels Manufacturer That Won't Fail

- Why Polyurethane is the Choice for Pallet Jack and Forklift Wheels

- Pallet Stacker Drive & Idler Wheels for Automated Warehouses

- Mold-on Polyurethane Wheels

- Analysis of the Causes of Cleanroom Stacker Polyurethane Wheel

- Why Are NDI Drive Rollers the Premier Choice for Pallets

- Polyurethane Wheels in Mining

93A Polyurethane Wheels for Heavy-Duty Metal Transportation

Polyurethane Wheels for Welding Rotator