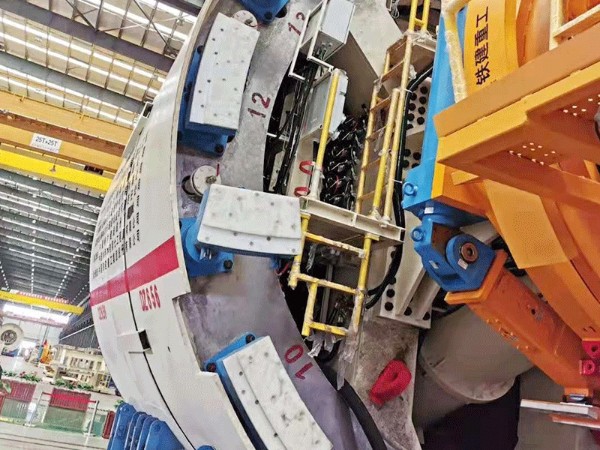

Custom Polyurethane Protective Plate of the Shield Machine

With excellent resilience, tear resistance, friction resistance, and corrosion resistance, the polyurethane protective plate for the shield machine has become an important anti-collision protection material for key parts of the shield machine.

Technical Information

With excellent resilience, tear resistance, friction resistance, and corrosion resistance, the polyurethane protective plate for the shield machine has become an important anti-collision protection material for key parts of the shield machine (such as the shield tail, walking system, thrust assembly, etc.), significantly improving equipment durability and construction safety.

In urban rail transit, underground pipe gallery and tunnel construction, the shield machine is a key tunneling equipment. When the shield machine passes through complex geological structures, its shell and cutterhead are susceptible to strong friction and impact. In order to prevent damage to key structures and extend the service life of the equipment, a special protective device, a shield machine protective plate, must be installed.

Among them, the polyurethane protective plate has gradually become the preferred material in the shield machine industry due to its excellent physical properties.

The role of the shield machine protective plate

Protect key components: The shield machine frequently contacts the rock and soil during operation, and the protective plate can effectively isolate the direct damage of external friction to the shell and cutterhead.

Buffering impact load: In the face of sudden geological changes or foreign body impact, the protective plate can absorb part of the impact energy, playing a buffering and shock-absorbing role.

Extending equipment life: By reducing wear and corrosion, the protective plate can significantly increase the service life of key parts of the shield machine and reduce the frequency of maintenance.

Easy to replace and maintain: Compared with directly replacing damaged parts, replacing the protective plate is faster and reduces downtime.

Advantages of the polyurethane anti-collision plate

High wear resistance: Polyurethane material has extremely high wear resistance and is suitable for dealing with high-frequency friction environments.

Excellent impact resistance: Its elastic structure can effectively buffer when subjected to force to prevent damage to the protective layer due to strong impact.

Corrosion resistance and oil resistance: It is still stable in geological environments containing water and corrosive liquids, and is suitable for various complex working conditions.

Low noise and low vibration: It helps to reduce construction noise and improve the operating environment.

Strong customizability: Polyurethane can be customized in size, thickness, and shape according to different shield machine models and operating requirements to meet personalized applications.

The polyurethane anti-collision plate of the shield machine is a key accessory to ensure the stable operation of the equipment. With its excellent wear resistance, impact resistance, and environmental adaptability, the polyurethane protective plate not only improves the efficiency and safety of shield construction but also helps enterprises effectively control maintenance costs.

You have questions, we have answers. Contact us today. Our skilled customer service specialists can help you make the right choice in polyurethane applications.

Cast Anti-Collision Polyurethane Plates

none