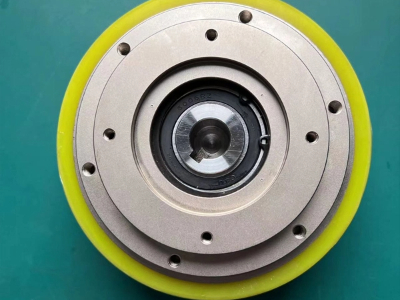

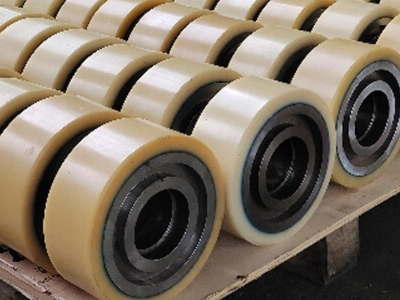

Lightweight and High-Strength MC Nylon Crane Pulley

MC Nylon crane pulleys are made of high-molecular polyamide as the core material, and have the characteristics of light weight and high load-bearing capacity, self-lubrication, friction and tear resistance, and silent operation.

Technical Information

MC Nylon crane pulleys are made of high-molecular polyamide as the core material. They are widely used in heavy-duty equipment such as cranes due to their light weight, high load-bearing capacity, self-lubrication, friction and tear resistance, and silent operation.

Advantages of nylon pulleys

1. Self-lubricating performance

Polyamide materials have good self-lubricating properties, which reduces dependence on external lubricants, reduces maintenance costs and environmental pollution risks, and avoids safety hazards caused by friction sparks on metal pulleys.

2. Lightweight and high-strength

Plastic pulleys have low density and light weight, which helps to reduce the load of the crane and improve overall performance.

3. Wear resistance and corrosion resistance

Nylon pulleys have excellent wear resistance and corrosion resistance, adapt to harsh environments, and extend service life. The hardness of nylon material is significantly lower than that of steel, and the wear rate of steel wire rope is only 1/8 of that of steel pulleys, which greatly extends the life of steel wire ropes by more than 8 times.

4. Low-noise operation

Nylon pulleys generate low noise during operation, which improves the working environment.

Application fields of polyamide crane pulleys

1. Tower crane boom system

As the core component of the luffing pulley group, the weight reduction reduces the weight of the tower crane lifting section by 12%, which is particularly suitable for the frequent lifting conditions of super high-rise buildings. After the application of a certain brand of QTZ160 tower crane, the replacement cycle of the wire rope was extended from 6 months to 4 years.

2. Mobile crane telescopic arm guide

In the 80-ton XCMG crane, the MC nylon slider is used as the boom guide component. Its self-lubricating property eliminates the problem of oil dripping, and the polymer polyethylene modified version can withstand the extremely cold working conditions of -50℃.

3. Port gantry crane wire rope steering wheel

The anti-corrosion property makes its life more than twice that of cast steel pulleys in the high humidity and high salt environment of the coast, and the annual maintenance cost of a single gantry crane is reduced by 180,000 yuan.

4. Heavy lifting of offshore platforms

The explosion-proof characteristics meet the safety standards of offshore operations, and the Kevlar reinforcement layer design meets the lifting needs of 3,000-meter deep-sea mining equipment.

Selection and maintenance suggestions

1. Choose the right nylon pulley

According to the working environment and load requirements of the crane, select the nylon pulley of the appropriate specifications and models to ensure that its performance meets the use requirements.

2. Regular inspection and maintenance

Regularly check the wear of the nylon pulley and replace the damaged parts in time to ensure the safe operation of the crane.

3. Cleaning and maintenance

Keep the pulley clean to avoid impurities from entering and affecting its performance; perform maintenance when necessary to extend its service life.

Polyamide pulleys have become an indispensable key component in modern lifting machinery due to their advantages such as light weight, high strength, self-lubrication, wear resistance and corrosion resistance. With the continuous development of engineering machinery technology, nylon pulleys will play an important role in more fields and promote the lifting industry to develop in a more efficient and safe direction.

You have questions, we have answers. Contact us today. Our skilled customer service specialists can help you make the right choice in polyurethane applications.

none

Nylon Gear for Nuclear Power Plants