Nylon Gear for Nuclear Power Plants

Nylon gears are essential engineering components to ensure the reliable and safe operation of nuclear power plants due to their light weight, heat resistance, corrosion resistance and maintenance-free operation.

Technical Information

In the demanding environment of nuclear power plants, reliability, safety, and performance are non-negotiable. Nylon gears have become essential engineering components in these settings due to their outstanding mechanical properties, environmental resistance, and maintenance-free operation. From control systems to fuel handling equipment, nylon gears offer efficient, durable, and cost-effective solutions.

Specific use scenarios of nylon gears in nuclear power plants

• Valve actuators and control mechanisms

Nylon gears are widely used in valve actuators, where precise control and low-friction operation are critical. Their ability to withstand high temperatures and exposure to radiation makes them suitable for these sensitive components.

• Fuel handling and robotic arms

In areas such as spent fuel movement and automated inspection systems, nylon gears ensure smooth, silent operation. Their lightweight nature reduces strain on robotic joints, while their resistance to corrosion and wear supports long-term reliability.

• Pump and auxiliary drive systems

Nylon gears are used in pumps and auxiliary mechanical systems where exposure to steam, oil, and chemicals is common. Their corrosion resistance and self-lubricating properties reduce the need for maintenance and minimize downtime.

• Instrumentation and monitoring equipment

Precision gears made of nylon are also found in monitoring and control panels, where quiet, reliable gear motion is required. These applications benefit from the gear’s dimensional stability and electrical insulation properties.

Advantages of nylon gears in nuclear applications

• Heat-resistant: Engineered nylon materials retain their strength and shape under high-temperature conditions, ensuring stable performance near heat sources like turbines or reactors.

• Corrosion-proof: Nylon does not rust or degrade in the presence of moisture, steam, radiation, or chemicals, making it ideal for harsh nuclear environments.

• Long-life and wear-resistant: Nylon gears resist wear and fatigue, even under continuous operation, extending their service life and reducing replacement frequency.

• Quiet operation: With a lower friction coefficient and shock absorption ability, nylon gears significantly reduce noise compared to metal gears.

• Lightweight and high strength: They offer an excellent strength-to-weight ratio, contributing to easier handling, lower energy consumption, and smooth mechanical response.

• Electrical insulation: Nylon prevents short circuits or electromagnetic interference in control systems, the latter critical for maintaining reactor safety protocols.

Nylon gears provide a reliable and efficient solution for various applications within nuclear power plants. Their exceptional resistance to heat, corrosion, and wear—combined with lightweight, quiet operation—makes them a smart choice for ensuring safety, stability, and performance in critical nuclear systems.

You have questions, we have answers. Contact us today. Our skilled customer service specialists can help you make the right choice in polyurethane applications.

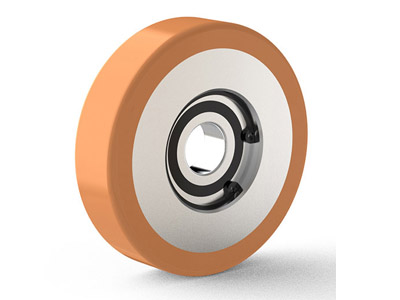

Lightweight and High-Strength MC Nylon Crane Pulley

none