Polyurethane Forklift and Pallet Wheels for Material Handling

Polyurethane forklift and pallet wheels are very important components in material handling, with the characteristics of durability, wear resistance, high load, and floor protection. Commonly used in w

Technical Information

Polyurethane forklift and pallet wheels are very important components in material handling, with the characteristics of durability, wear resistance, high load, and floor protection. Commonly used in warehousing and logistics, automotive manufacturing, food and pharmaceuticals, ports and cold chain logistics, the following introduces the types, characteristics and applicable scenarios of polyurethane forklift wheels.

The main advantages of polyurethane forklift wheels

• Durability and load capacity: Polyurethane wheels have a hardness range of shore a 80-95, can withstand heavy loads (up to several tons per wheel), and can resist wear on rough surfaces.

• Chemical resistance: Unlike rubber, polyurethane wheels will not degrade in oily or chemical environments, ensuring a long service life in industrial environments.

• Noise reduction and shock absorption: High elasticity minimizes vibrations, protecting operators and fragile goods during transportation.

• Markless and clean room compliant: PU wheels will not leave any wear marks on the ground, which is very suitable for warehouses with epoxy coatings or facilities that require a sterile environment.

Classification of forklift wheels

Forklift wheels are classified according to their position and function as follows:

• Pallet wheels (forklift guide wheels)

Function: These wheels are mounted on the front of the forklift forks to guide and stabilize the pallet during lifting.

Features: Compact size (80-120 mm in diameter), solid PU structure for precise maneuverability, and not easily deformed under pressure.

• Drive wheel (power wheel)

Function: Transmit the power of the forklift motor to achieve movement.

Features: Tread pattern or groove design for enhanced traction; reinforced metal core to ensure structural integrity; and heat-resistant polyurethane formula for high-intensity operations.

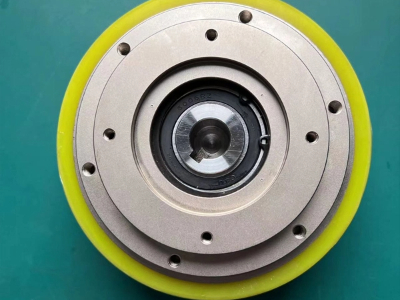

• Load wheel (load-bearing wheel)

Function: Support most of the weight of the forklift and cargo load.

Features: Larger diameter (up to 300 mm or more); double-row ball bearings for smooth rotation; thickened polyurethane layer for evenly distributed stress.

• Swivel wheel (universal wheel)

Function: Provide directional control and balance when turning.

Features: 360° rotation capability; braking system to ensure stability; and shock-absorbing polyurethane design for uneven roads.

| Non marking tread | Yes | Tread description | low rolling resistance noise reduction high load-bearing wear-resistant |

| Wheel diameter (mm) | 85(customizable) | Type of wheel | pallet rollers |

| Wheel width (mm) | 80-120(customizable) | Temperature | -20 / +70°C |

| Load capacity (kg) | 400-1000(customizable) | Hub length (mm) | 46-116(customizable) |

| Bearing type | precision ball bearing | Axle hole-Ø (mm) | 20(customizable) |

| Hardness of tread | 85-95° Shore A(customizable) | Tread | vulcanized polyurethane tread |

Industry application of polyurethane forklift wheels

Polyurethane wheels can meet various operational needs in various industries:

• Warehousing and logistics

High-traffic distribution centers prefer non-marking polyurethane wheels to protect the ground, while their high load capacity supports standardized pallet handling.

• Manufacturing and automobile

Heavy-duty polyurethane wheels can be used to transport mechanical parts and raw materials to prevent oil spills and chemical contact in factory environments.

• Food and pharmaceuticals

FDA-compliant polyurethane wheels meet hygiene standards and have anti-static functions to prevent dust accumulation in clean rooms and processing areas.

• Ports and cold chain logistics

Corrosion-resistant polyurethane wheels can withstand the high salt and humidity environment of ports. Low-temperature polyurethane wheels remain flexible in freezers (-40°c).

Philson polyurethane forklift wheels can be configured as anti-static, low flame retardant, high temperature or low temperature polyurethane forklift wheels according to needs to ensure safe, efficient and precise movement of materials. Contact us for relevant quotes.

You have questions, we have answers. Contact us today. Our skilled customer service specialists can help you make the right choice in polyurethane applications.

Cleanroom Polyurethane Travel Wheels

AGV Drive Wheel And Travel Wheel Replacement