- WhatsApp: +86 19941574798

- sale06@kfqizhongji.com

Why More Warehouses Are Switching to Polyurethane Pallet Wheels

Polyurethane pallet wheels offer superior load-bearing performance, chemical resistance, and quiet operation. Ideal for pallet jacks and warehouse equipment, they ensure durability, protect floors, and improve efficiency in demanding environments.

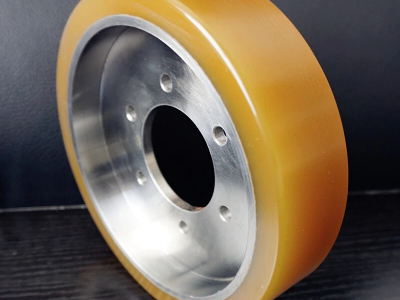

As the demand for speed, efficiency, and cleanliness in warehouses increases, many facilities are upgrading their equipment, starting from the ground up. One key component seeing widespread adoption is the polyurethane pallet forklift wheel. Whether for drive wheels, pallet jack wheel replacements, or load-bearing wheels, polyurethane is becoming the material of choice for warehouse forklift operations.

Why polyurethane wheels matter in warehousing

Warehouse floors are often smooth, coated, and sensitive to wear. Traditional rubber or metal wheels may cause floor damage, generate excessive noise, or fail due to chemical exposure. Polyurethane offers solutions to these challenges and more:

Key advantages

• Floor protection – polyurethane wheels reduce scuffing, scratching, and wear on epoxy and concrete floors.

• High load capacity – ideal for carrying heavy pallets while maintaining shape and integrity under pressure.

• Friction and wear resistance – excellent performance in high-traffic, high-load applications.

• Chemical corrosion resistance – resists oils, solvents, and cleaning agents commonly found in warehouses.

• Waterproof & moisture-proof – suitable for humid or wet environments.

• Noise reduction – polyurethane absorbs vibrations and sound, making forklifts quieter and more operator-friendly.

• High rebound & energy efficiency – reduces rolling resistance for smoother, more efficient travel.

• No degumming or delamination – advanced bonding prevents separation even under heavy use.

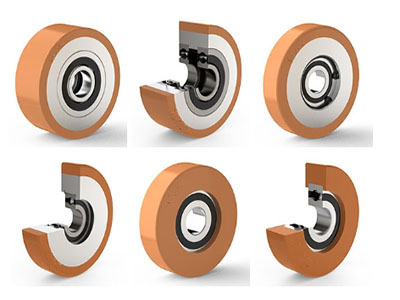

Classification of polyurethane wheels in forklifts

Polyurethane wheels are engineered for different forklift roles. Here’s how they are categorized:

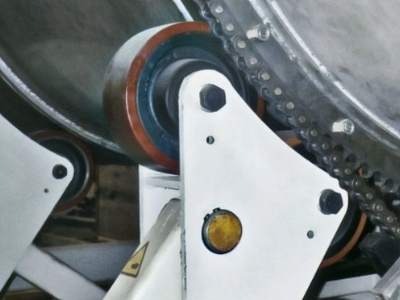

• Polyurethane drive wheels

Function: Transmit power from the motor to the floor.

Use: Common in electric forklifts, AGVs, and warehouse stackers.

Benefits: Strong grip, wear resistance, and quiet operation on indoor floors.

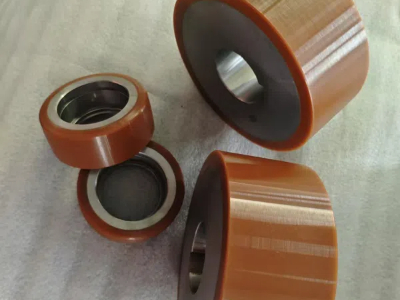

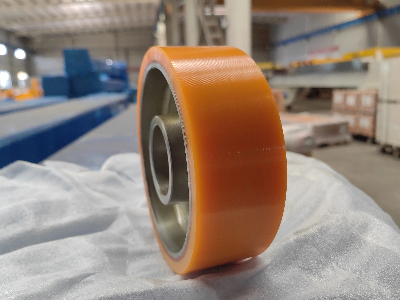

• Load wheels (front/rear load or fork-end wheels)

Function: Bear the load on pallet trucks and forklifts.

Use: Found in pallet jacks, walkie stackers, and order pickers.

Benefits: High weight-bearing, low rolling resistance, and minimal floor damage.

• Caster wheels (swivel wheels)

Function: Provide mobility and turning capability.

Use: Ideal for narrow aisle and cleanroom forklifts.

Benefits: Reduce turning noise and vibration; offer smooth steering.

• Support/stabilizer wheels

Function: Provide extra stability, especially in three-wheel forklifts or multi-directional lift trucks.

Benefits: Balanced movement over uneven floors or transitions.

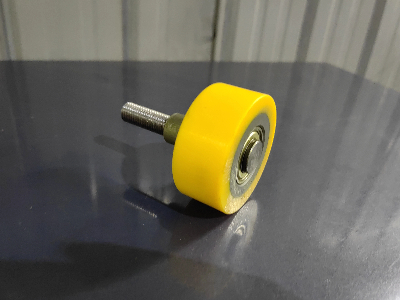

• Press-on polyurethane wheels

Function: Compact wheels that press onto hubs, typically in electric forklifts.

Benefits: Small in size but heavy-duty in performance and durability.

Conclusion

More and more warehouses are recognizing the importance of upgrading to polyurethane forklift wheels. Whether you're replacing worn-out pallet jack wheels or optimizing your drive wheel performance, polyurethane offers a long-lasting, quiet, and efficient solution that outperforms traditional materials in modern warehousing conditions.

Categories

Recent Cases

Recent Products

Recent Blogs

- What industries benefit most from using polyurethane industrial wheels?

- How do polyurethane wheels compare to metal wheels?

- Applications of Polyurethane Wheels in Mining

- How do you maintain polyurethane wheel longevity?

- How To Choose Industrial Wheels For Amusement Rides

- Polyurethane Wheels Noise Reduction 70 Percent Quieter

- Polyurethane Coated Wheels Superior Performance Advantages

- Advantages of Heavy-Duty Polyurethane Cast Iron Wheels

- Why Are NDI Drive Rollers the Premier Choice for Pallets?

- How Vulkollan® Wheels Enhance Stacker Performance

Advantages of Heavy-Duty Polyurethane Cast Iron Wheels

High-Quality Polyurethane Fork Wheels from China Manufacturer