-

WhatsApp: +86 19941574798

WhatsApp: +86 19941574798

-

sale06@kfqizhongji.com

sale06@kfqizhongji.com

Mining Monorail Hoisting Equipment

Polyurethane Wheels for Mining Monorail Hoists

How polyurethane-coated wheels revolutionize mining monorail hoists. With high load - bearing, extreme wear resistance, and safety adaptability, they solve pain points, reduce costs, and enhance efficiency.

As a core equipment for transporting materials and personnel in narrow underground roadways, the operational stability of mining monorail hoists is directly related to mining efficiency and operational safety. As the only load-bearing component that connects the monorail hoist to the track, the wheels must withstand extreme working conditions such as heavy loads, high friction, and excessive impurities. Traditional steel wheels are prone to slipping and high noise, while rubber-coated wheels suffer from insufficient wear resistance and easy aging, which have long been bottlenecks restricting the performance improvement of monorail hoists. With the composite characteristics of high load-bearing, strong wear resistance, and impact resistance, polyurethane-coated wheels accurately solve the operational pain points of mining monorail hoists and have become the preferred solution for wheel upgrades in this field.

I. Severe Working Conditions of Mining Monorail Hoists: Three Core Requirements for Wheels

The particularity of the underground mining environment imposes stricter performance standards on monorail hoist wheels than conventional scenarios, which can be summarized into three core requirements:

Super Strong Load-Bearing Capacity: Monorail hoists need to frequently transport heavy materials such as ore and support materials, with a single wheel load often reaching 5-8 tons. They also need to operate stably in inclined roadways (with a maximum inclination angle of 30°). This requires wheels to have excellent compression deformation resistance to avoid wheel cracking caused by long-term heavy loads.

Extreme Wear Resistance and Impurity Resistance: Underground roadways are filled with hard impurities such as coal dust and rock chips, which easily cause "abrasive wear" during the friction between wheels and tracks. The average service life of traditional rubber wheels is only 1-2 months. At the same time, the impact at track joints will aggravate wheel surface wear, requiring wheels to have both high hardness and elastic buffering.

Safety Adaptability: Flammable and explosive gases such as gas exist underground, so wheels must have anti-static performance (surface resistivity ≤ 10⁸Ω). In addition, the low-temperature and high-humidity environment requires wheels to be resistant to aging and embrittlement to ensure all-weather safe operation.

Traditional wheel materials cannot meet the above requirements simultaneously. However, through material modification and structural optimization, polyurethane-coated wheels achieve precise matching with working condition requirements.

II. Core Advantages of Polyurethane-Coated Wheels: Targeted Solutions to Working Condition Pain Points

To meet the operational needs of mining monorail hoists, professional manufacturers have created special-coated wheels suitable for mining scenarios by adjusting the polymerization degree of polyurethane and adding modified fillers. Their core advantages are concentrated in the following four aspects:

1. Heavy Load and Deformation Resistance: Load-Bearing Performance Comparable to Steel Wheels

High-modulus polyurethane material (tensile strength ≥ 35MPa, Shore hardness 95-98A) is adopted, and the coating layer is tightly combined with the steel wheel core through the thermal vulcanization process to avoid the risk of debonding. Test data shows that a polyurethane-coated wheel with a diameter of 300mm can bear a static load of 10 tons, and the compression deformation rate during dynamic operation is ≤ 2%, which is much higher than that of traditional rubber wheels (deformation rate ≥ 8%). Even when transporting heavy materials in a 30° inclined roadway, the wheel surface can maintain a stable shape without obvious depression.

2. Safety Adaptability: Meeting Special Underground Environment Requirements

Customized formulas enable polyurethane-coated wheels to have multiple safety features: after adding antistatic agents, the surface resistivity is stable at 10⁶-10⁸Ω, complying with the Coal Mine Electromechanical Equipment Safety Standard; after low-temperature modification, the elastic retention rate is ≥ 90% in the underground environment of -20℃, with no risk of embrittlement; at the same time, polyurethane materials do not absorb coal dust and rock chips, and the wheel surface is easy to clean, reducing track wear caused by impurity jamming.

3. Cost Reduction and Efficiency Improvement: Reducing Operation and Maintenance Costs and Downtime

The long service life of polyurethane-coated wheels directly reduces the replacement frequency. After being used in a large coal mine, the replacement cycle of monorail hoist wheels has been extended from 1.5 months to 12 months, and the annual replacement times have decreased from 8 to 1, saving more than 2800 USD in wheel procurement costs per unit equipment annually. In addition, their low friction coefficient (0.18-0.22) reduces the energy consumption of the monorail hoist's drive motor by 10%, and the operating noise is reduced from 85 decibels (steel wheels) to 65 decibels, improving the underground working environment.

III. Customized Solutions for Polyurethane-Coated Wheels: Adapting to Different Types of Monorail Hoists

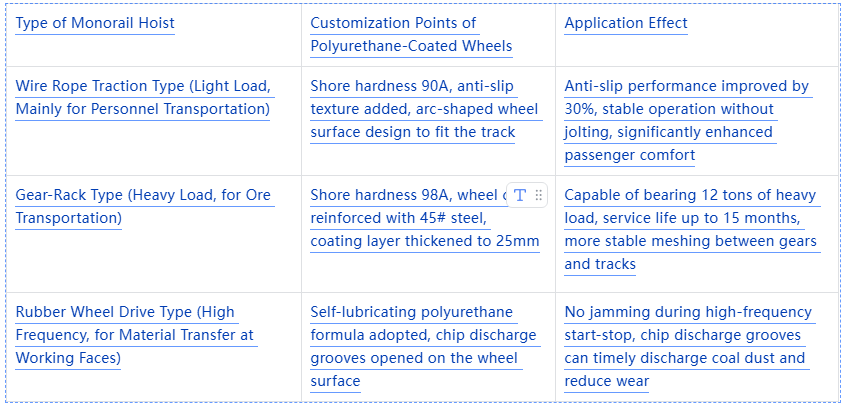

Mining monorail hoists can be divided into wire rope traction type, gear-rack type, rubber wheel drive type and other types according to the drive mode. Polyurethane-coated wheels need to be precisely adapted through customized design:

IV. Application Case: Upgrade Effect of Polyurethane-Coated Wheels on a Coal Mine Monorail Hoist

A coal mine in Shanxi with an annual output of 5 million tons originally used steel wheels for its 3 underground gear-rack monorail hoists, which had problems such as high noise, rapid track wear, and monthly shutdowns for wheel replacement. After introducing customized polyurethane-coated wheels in 2023, three core improvements were achieved:

Safety Improvement: No wheel failures occurred within 10 months of operation, the qualification rate of anti-static testing was 100%, and no transportation interruptions caused by wheel problems occurred.

Cost Optimization: The annual wheel procurement cost per monorail hoist decreased from 450 USD to 700 USD , track wear was reduced by 60%, and annual track maintenance costs were saved by 2500 USD.

Efficiency Enhancement: The shutdown time for wheel replacement was reduced from 8 hours per month to 4 hours per year, the annual effective transportation time of the monorail hoist increased by 92 hours, and the ore transportation volume was indirectly increased by 12,000 tons.

V. Conclusion: Polyurethane-Coated Wheels Become the Core Choice for Mining Monorail Hoist Upgrades

The requirement of mining monorail hoists perfectly matches the heavy load resistance, wear resistance and safety adaptability characteristics of polyurethane-coated wheels. With the continuous upgrading of polyurethane material modification technology, their performance in high and low temperature resistance, corrosion resistance and other aspects will be further improved. In the future, they are expected to adapt to monorail hoist equipment in deeper underground and more complex working conditions. For mining enterprises, choosing customized polyurethane-coated wheels is not only a simple replacement of wheel components, but also a key measure to improve the operational efficiency of monorail hoists and reduce operation and maintenance costs.

If you need to customize polyurethane-coated wheel solutions according to the specific model of the mining monorail hoist, you can contact professional manufacturers to conduct working condition testing and personalized design, so as to achieve precise matching between component performance and equipment requirements. Contact us!

Categories

Recent Cases

Recent Products

Recent Blogs

- How Do Polyurethane Wheels Compare To Metal Wheels

- Why Choose Injected Polyurethane (TPU) Wheels for Your Equipment

- Why Roller Coasters Use NDI Polyurethane Wheels

- How to Choose a Poly Wheels Manufacturer That Won't Fail

- Why Polyurethane is the Choice for Pallet Jack and Forklift Wheels

- Pallet Stacker Drive & Idler Wheels for Automated Warehouses

- Mold-on Polyurethane Wheels

- Analysis of the Causes of Cleanroom Stacker Polyurethane Wheel

- Why Are NDI Drive Rollers the Premier Choice for Pallets

- Polyurethane Wheels in Mining

Polyurethane Wheels for Load-Haul Dumpers in the Mining Industry

none