-

WhatsApp: +86 19941574798

WhatsApp: +86 19941574798

-

sale06@kfqizhongji.com

sale06@kfqizhongji.com

Material Handling Drive System

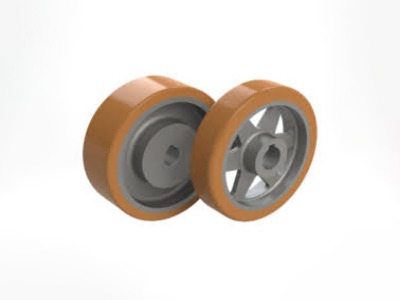

Wear-Resistant Vulkollan AGV Drive Wheel

The Vulkollan AGV drive wheel features high elasticity, wear resistance, and low noise. It is suitable for high-speed and high-frequency operation environments, improves AGV positioning accuracy and operation stability.

The Vulkollan AGV drive wheel features high elasticity, wear resistance, and low noise. It is suitable for high-speed and high-frequency operation environments, improves AGV positioning accuracy and operation stability, and is an ideal choice for smart warehousing. The following introduces the material, performance characteristics, functions, and usage scenarios of Vulkollan wheels.

Vulkollan material introduction

Vulkollan is a high-performance polyurethane elastomer developed by Covestro in Germany. It is based on naphthalene diisocyanate (NDI) and is cast through a special process. Compared to traditional polyurethane, Vulkollan exhibits higher mechanical properties and a stronger dynamic load capacity.

Vulkollan's key performance characteristics include:

• High elasticity and tear resistance: It maintains a stable grip and prevents structural defects in high-frequency start-stop AGV operations.

• Extreme fatigue resistance: Extend the service life of the wheel and reduce the frequency of replacement.

• Low compression set rate: not easy to deform under long-term static load, and adapt to a longer state.

• Oil-resistant, chemical-resistant, and corrosion-resistant: suitable for a variety of warehouse environments, such as food, chemical, e-commerce, and other industries.

• Good shock absorption performance: reduces operating noise and vibration, improves operating comfort and cargo safety.

The role of Vulkollan drive wheels in AGV systems

• Dual-task of load-bearing and driving

The drive wheel not only bears the weight of the AGV body, but is also responsible for the forward and steering of the drive system, so it places extremely high demands on the traction and load performance of the wheel. Vulkollan material has high kinetic energy capacity, which can achieve stable operation at high speed, gap start, and stop.

• Improve positioning accuracy

Warehouse automation has extremely high requirements for path accuracy, especially when shuttling between narrow aisles or dense shelves. Vulkollan tires have excellent rolling bearing and friction control capabilities, allowing AGVs to maintain precise trajectory operation.

• Adapt to high-intensity work

Warehouse AGVs usually operate continuously for 24 hours, which places extremely high demands on the reliability of the drive wheel. Vulkollan has excellent fatigue resistance and high temperature stability, and can adapt to various continuous loads and environmental changes.

• Low noise operation

In intelligent industrial environments with strict noise control requirements, Vulkollan wheels can provide a quiet and smooth operation experience, reduce equipment operation noise, and provide a good working environment.

AGV polyurethane wheel application scenarios and cases

• Intelligent warehousing and logistics centers: a cast iron core or aluminum alloy wheel core can meet the use requirements of high load and high operation.

• Production lines in the automotive, electronics, home appliances, and other manufacturing industries: AGV drive wheels with aluminum core and cast iron core can achieve fast start and braking.

• Food and pharmaceutical industries: Polyurethane wheels with stainless steel wheel cores can be dust-free and anti-static.

Vulkollan polyurethane AGV drive wheels, with their excellent load-bearing capacity and rolling performance, have become key components in warehouse automation upgrades. Vulkollan AGV drive wheels are ideal for efficient, safe, and intelligent logistics systems.

If you need to customize Vulkollan AGV drive wheels with different load levels, mounting structures, or environmental requirements, please contact us for professional solutions.

Categories

Recent Cases

Recent Products

Recent Blogs

- Why Choose Injected Polyurethane (TPU) Wheels for Your Equipment

- Pallet Stacker Drive & Idler Wheels for Automated Warehouses

- Mold-on Polyurethane Wheels

- Analysis of the Causes of Cleanroom Stacker Polyurethane Wheel

- Why Are NDI Drive Rollers the Premier Choice for Pallets

- Polyurethane Wheels in Mining

- How Do You Maintain Polyurethane Wheel Longevity

- How Do Polyurethane Wheels Compare To Metal Wheels

- What Industries Benefit Most From Using Polyurethane Industrial Wheels

- Polyurethane Forklift Wheels for Warehousing Pallet Handling

Polyurethane Wheels in Heavy-Duty Pallet Trucks

High-performance Polyurethane AGV Drive Wheels