-

WhatsApp: +86 19941574798

WhatsApp: +86 19941574798

-

sale06@kfqizhongji.com

sale06@kfqizhongji.com

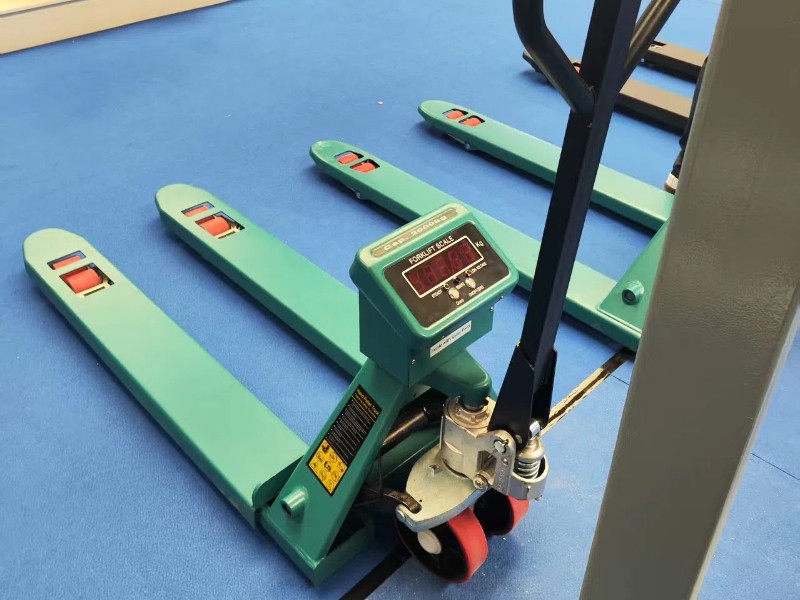

Material Handling Drive System

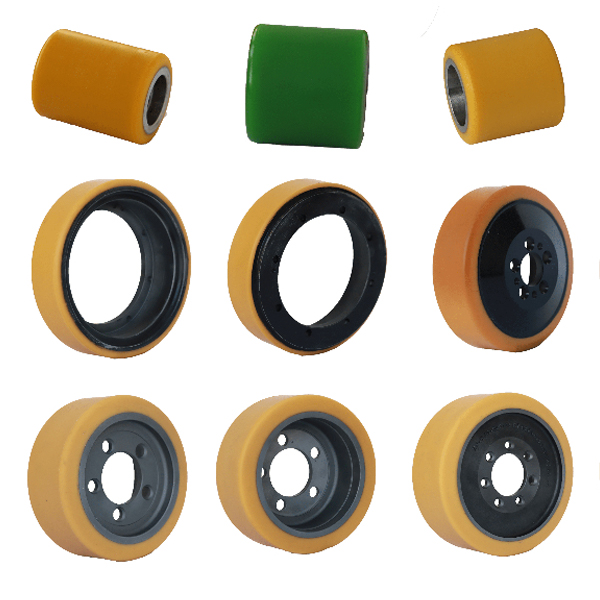

Polyurethane Wheels in Heavy-Duty Pallet Trucks

Cast polyurethane wheels have the characteristics of high load-bearing capacity, friction resistance, impact resistance, tear resistance, silent rebound, etc., and are used for material handling and transportation in heavy-duty pallet trucks.

Cast polyurethane wheels have the characteristics of high load-bearing capacity, friction resistance, impact resistance, tear resistance, silent rebound, strong adhesion, etc., and are used for material handling and transportation in heavy-duty pallet trucks. The following introduces the definition, characteristics, and usage scenarios of cast polyurethane wheels.

Definition of cast polyurethane wheels

Cast polyurethane wheels are high-strength, high-performance wheels made by heating and melting the pre-treated polyurethane raw materials, pouring them into a mold and coating them on a metal wheel core (such as aluminum core, cast iron core, steel core) through curing, post-treatment and other processes.

Characteristics of heavy-duty pallet truck wheels

High load-bearing capacity

Polyurethane materials have excellent compressive resistance and can withstand the impact and load of pallet trucks frequently carrying heavy objects. They are suitable for the transportation of heavy goods.

Wear and tear resistance

Compared with traditional rubber wheels or nylon wheels, polyurethane wheels have higher wear resistance, which can reduce wear caused by ground friction and extend service life.

Silent shock absorption

Polyurethane wheels have moderate elasticity, can effectively absorb vibrations, and reduce noise during handling. They are suitable for noise-sensitive environments such as warehouses, hospitals, laboratories, etc.

Resistant to chemicals and oils

Polyurethane materials have good resistance to grease, solvents and most chemicals, and are suitable for use in food processing, chemical and other industries.

No damage to the ground

Polyurethane wheels are soft in texture and will not scratch sensitive floors such as epoxy floors and tiles like metal or hard plastic wheels. They are suitable for clean workshops, warehousing and logistics and other places.

Anti-slip stability

Polyurethane wheels have good grip and can maintain stable operation even on wet or uneven surfaces, reducing the risk of slipping.

Application scenarios of polyurethane forklift wheels

Warehousing and logistics

Applicable to forklifts, manual or electric pallet trucks, efficient handling of goods in warehouses, and reducing the impact of tire wear on the ground.

Food and pharmaceutical industries

Meet hygiene requirements, corrosion-resistant and pollution-free, suitable for cold storage, clean workshops and other environments.

Manufacturing and workshops

In industrial scenarios such as heavy machinery and automobile assembly, polyurethane wheels can withstand high loads and protect the ground.

Retail and supermarkets

The quiet characteristics make it suitable for use in places such as shopping malls and supermarkets to avoid noise interference.

Ports and freight stations

The wear and impact resistance characteristics are suitable for use in high-intensity working environments such as container handling and freight loading and unloading.

Polyurethane wheels are ideal for pallet trucks due to their durability, quietness and ground protection capabilities, especially for scenarios with high requirements for ground protection, noise control and load capacity. Whether it is warehousing and logistics, food and medicine or manufacturing, polyurethane wheels can provide efficient and stable handling solutions.

Categories

Recent Cases

Recent Products

Recent Blogs

- How Do Polyurethane Wheels Compare To Metal Wheels

- Why Choose Injected Polyurethane (TPU) Wheels for Your Equipment

- Why Roller Coasters Use NDI Polyurethane Wheels

- How to Choose a Poly Wheels Manufacturer That Won't Fail

- Why Polyurethane is the Choice for Pallet Jack and Forklift Wheels

- Pallet Stacker Drive & Idler Wheels for Automated Warehouses

- Mold-on Polyurethane Wheels

- Analysis of the Causes of Cleanroom Stacker Polyurethane Wheel

- Why Are NDI Drive Rollers the Premier Choice for Pallets

- Polyurethane Wheels in Mining

Shock-Absorbing Heavy Duty Polyurethane for Forklift Wheels

High-performance Polyurethane AGV Drive Wheels