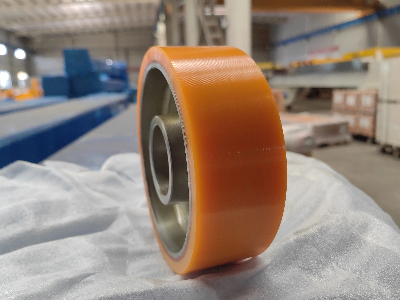

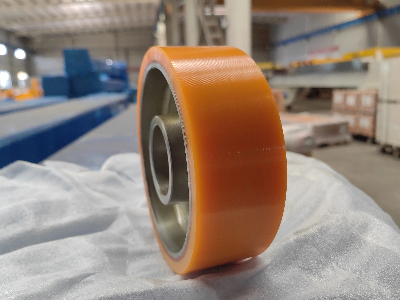

Electric Pallet Truck Drive Wheel

In modern material handling scenarios like logistics, warehouses, and manufacturing plants, the drive wheels of electric pallet trucks not only support weight but also provide traction, steering, and stability.

Technical Information

In modern material handling scenarios like logistics, warehouses, and manufacturing plants, the drive wheels of electric pallet trucks not only support weight but also provide traction, steering, and stability.

What are the drive wheels on electric pallet trucks?

The drive wheel is located at the front of the truck and is directly connected to the motor and steering system. Unlike load wheels, which only bear static weight, the drive wheel carries weight and transmits torque, moving the pallet truck forward and backward. It also supports steering, which means it is subject to greater stress and more complex operating conditions than other wheels on the vehicle.

Drive wheel capacity

Standard electric pallet trucks (total load capacity of 1.5-2.5 tons): A single drive wheel typically carries 800-1200 kg.

Heavy-duty electric pallet trucks (total load capacity of 3-5 tons): The drive wheel can carry 1200-2000 kg.

Selecting the appropriate load capacity is crucial, as undersized drive wheels can lead to premature wear, reduced efficiency, and even operational risks. Proper drive wheels ensure smoother, safer operation and a longer service life for your pallet truck. Drive Wheel Material

Polyurethane (PU) drive wheel

High load capacity, excellent wear resistance, and low noise.

Provides strong traction while protecting the floor.

A popular and versatile choice for warehouses and logistics centers.

Nylon drive wheel

Extremely hard surface, low rolling resistance, and high-temperature resistance.

Poor cushioning, noisy operation, and unfriendly to the floor.

Suitable for smooth concrete floors where long-distance travel is required.

Choose the right Wheel for different applications

Warehouses and distribution centers: PU drive wheels are an ideal choice due to their balance of durability, load capacity, and noise reduction.

Smooth concrete floors: Nylon wheels offer high rolling efficiency but may increase noise levels.

For ramps and heavy loads: Heavy-duty pallet driver rollers are recommended for superior traction and strength.

Philson's brand strength and customization capabilities

Philson combines advanced polyurethane casting and bonding technology with strict quality control to create reliable polyurethane ring running wheels. Our in-house expertise in precision molding, Vulkollan polyurethane thickness optimization, and metal core bonding ensures exceptional wear resistance and a long service life for our drive wheels. We specialize in customized load-bearing solutions, tailoring drive wheel designs to suit different electric pallet truck models, load capacities, and operating environments. We provide superior service to customers in logistics, warehousing, and heavy industry. For custom requirements or more information, please contact us at sale06@kfqizhongji.com or via Whats app: 19941574798.

You have questions, we have answers. Contact us today. Our skilled customer service specialists can help you make the right choice in polyurethane applications.

Electric Monorail Transport System Wheels

Precision Wheels for Semiconductor Stocker Equipment