-

WhatsApp: +86 19941574798

WhatsApp: +86 19941574798

-

sale06@kfqizhongji.com

sale06@kfqizhongji.com

Advantages of Heavy-Duty Polyurethane Cast Iron Wheels

Polyurethane tread heavy-duty wheels with cast iron cores are used in various industries, including heavy-duty material handling, due to their excellent strength, durability, and operating efficiency.

Polyurethane tread heavy-duty wheels with cast iron cores are used in various industries, including heavy-duty material handling, due to their excellent strength, durability, and operating efficiency. These wheels are engineered to meet the demands of rigorous material handling, offering key benefits in performance-critical applications.

Cast iron core parameters and performance

High strength: Compressive strength reaches ≥600 MPa, capable of withstanding heavy loads.

Hardness: Generally ranges from HB 180–240, offering wear and impact resistance.

Dimensional stability: Minimal thermal deformation, suitable for long-term, heavy-duty use.

Processability: Easy to turn, mill, and drill, ensuring a tight bond with the polyurethane layer.

Fatigue resistance: Resists cracking under repeated stress, ensuring a long service life.

Polyurethane cover parameters and performance

Hardness range: Shore A 70–98 or Shore D 50–70, customizable depending on the application.

Tensile strength: ≥25 mpa, offering excellent toughness.

Tear strength: ≥80 kn/m, offering strong cut and tear resistance.

Abrasion resistance: Wear is only 1/5–1/10 of that of rubber, ensuring a long service life.

Weather resistance: Resists oil, hydrolysis, ozone, and various chemical corrosion.

Elasticity and cushioning: Maintains excellent elasticity and shock absorption properties even at low temperatures and high loads.

Advantages of polyurethane wheels

• High load capacity and structural strength

The cast iron core provides exceptional structural integrity, making these wheels suitable for heavy loads and high-impact operations. Industries that rely on transporting bulky machinery or heavy pallets—such as automotive, steel processing, and logistics—benefit from the wheel’s strength and stability under pressure.

• Wear and tear resistance

The polyurethane tread offers excellent abrasion resistance, significantly extending service life even in environments with rough surfaces or continuous use. Unlike rubber wheels, polyurethane does not crack or deform under prolonged stress, which reduces downtime and replacement costs.

• Floor protection and noise reduction

Polyurethane treads are gentle on industrial flooring and help reduce operational noise. This makes them ideal for indoor environments such as warehouses and factories where both cleanliness and noise control are critical.

• Chemical and oil resistance

Many industrial settings expose wheels to oils, greases, and solvents. Polyurethane has excellent resistance to these chemicals, maintaining its performance and integrity without swelling or degradation, which is essential in manufacturing and machining facilities.

• Heat and cold tolerance

Polyurethane wheels retain their performance characteristics across a wide range of temperatures. Whether operating in cold storage or high-heat environments, they maintain traction and flexibility.

Usage scenarios

• Forklifts and pallet trucks: For moving heavy loads efficiently and safely.

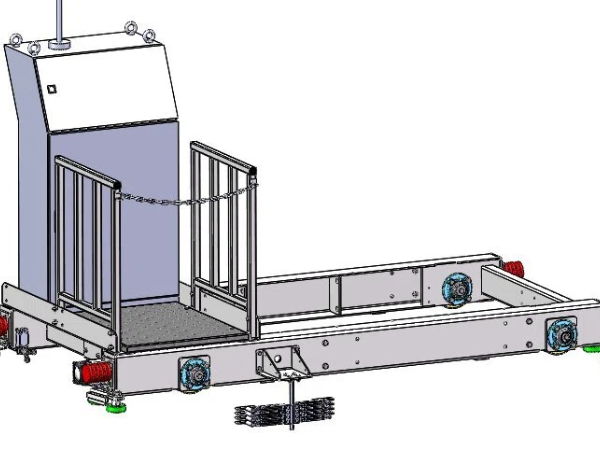

• Automated guided vehicles (AGVs): For smooth, quiet operation in controlled environments.

• Conveyor systems and production lines: Where consistent movement and wear resistance are needed.

• Heavy machinery platforms: Supporting high weights without compromising maneuverability.

In summary, heavy-duty urethane wheels with cast iron cores combine the resilience of metal with the surface benefits of polyurethane, making them a top choice in demanding industrial environments.

Categories

Recent Cases

Recent Products

Recent Blogs

- How Do Polyurethane Wheels Compare To Metal Wheels

- Why Choose Injected Polyurethane (TPU) Wheels for Your Equipment

- Why Roller Coasters Use NDI Polyurethane Wheels

- How to Choose a Poly Wheels Manufacturer That Won't Fail

- Why Polyurethane is the Choice for Pallet Jack and Forklift Wheels

- Pallet Stacker Drive & Idler Wheels for Automated Warehouses

- Mold-on Polyurethane Wheels

- Analysis of the Causes of Cleanroom Stacker Polyurethane Wheel

- Why Are NDI Drive Rollers the Premier Choice for Pallets

- Polyurethane Wheels in Mining

Advantages of Anti-Skid Polyurethane Wheels in the Food Industry

Why Polyurethane is the Choice for Pallet Jack and Forklift Wheels