-

WhatsApp: +86 19941574798

WhatsApp: +86 19941574798

-

sale06@kfqizhongji.com

sale06@kfqizhongji.com

Mining Monorail Hoisting Equipment

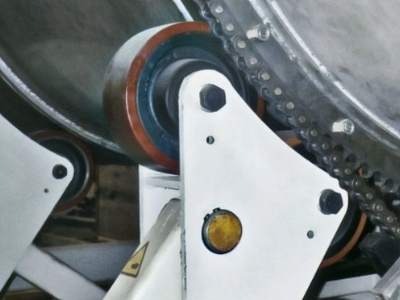

Usage in Gravel Quarry for Screening Drums Drive Support Wheels

VULKOLLAN® drive support wheels for gravel quarry screening drums offer high load capacity, shock absorption, and abrasion resistance, ensuring reliable performance in harsh, sandy conditions.

In the demanding environment of gravel and sand quarries, screening drums play a vital role in sorting and classifying raw materials. These massive rotating drums rely on a combination of drive wheels, support/load-bearing wheels, and idler wheels to keep operations running smoothly and continuously.

Roles of the wheels in a screening drum

Drive wheels

Drive wheels transmit torque from the motor to the drum, ensuring steady and controlled rotation. They must provide strong traction and withstand high torsional forces, even when the drum is fully loaded with aggregate.

Support / load-bearing wheels

These wheels carry the enormous static and dynamic weight of the drum, including the bulk material inside. They help maintain drum alignment and reduce wear on structural components by evenly distributing the load.

Drum idler wheels

Idler wheels provide additional stability, guiding the drum’s movement while minimizing vibration and lateral drift during operation.

Challenges in quarry applications

Quarry environments present extreme working conditions for wheels:

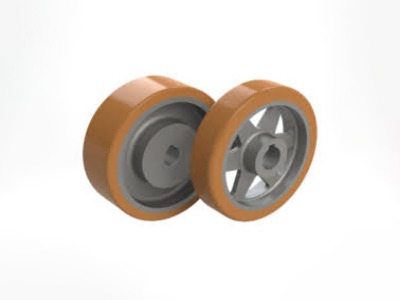

Heavy loads: The 600 mm diameter × 200 mm wide vulkollan® load-bearing wheels must support significant weight without deformation.

Impact forces: Large stones and uneven material flow generate sudden shock loads.

Abrasive materials: Sand and gravel particles cause constant wear if materials are not properly resistant.

Environmental stress: Heat, dust, and fluctuating weather conditions demand materials with dimensional stability and consistent performance.

Why polyurethane, and specifically vulkollan®?

Vulkollan®, a high-performance polyurethane, is the preferred choice for quarry screening drum wheels because of its unmatched combination of:

Outstanding load capacity – maintains structural integrity under extreme weights.

Excellent impact absorption – damps shock loads to protect the drum and drive system.

Superior abrasion resistance – handles the constant contact with sand and gravel without excessive wear.

Dimensional stability – maintains shape and performance under high pressure and varying temperatures.

Low rolling resistance – reduces energy consumption and wear on drive components.

Custom-built for your quarry needs

We offer tailor-made vulkollan® and polyurethane wheels in different diameters, widths, and hardness levels to fit your specific drum design and operational requirements. Whether you need drive wheels, support/load-bearing wheels, or idler wheels, our engineered solutions deliver maximum uptime, reduced maintenance costs, and long-term durability.

Categories

Recent Cases

Recent Products

Recent Blogs

- Why Choose Injected Polyurethane (TPU) Wheels for Your Equipment

- Pallet Stacker Drive & Idler Wheels for Automated Warehouses

- Mold-on Polyurethane Wheels

- Analysis of the Causes of Cleanroom Stacker Polyurethane Wheel

- Why Are NDI Drive Rollers the Premier Choice for Pallets

- Polyurethane Wheels in Mining

- How Do You Maintain Polyurethane Wheel Longevity

- How Do Polyurethane Wheels Compare To Metal Wheels

- What Industries Benefit Most From Using Polyurethane Industrial Wheels

- Polyurethane Forklift Wheels for Warehousing Pallet Handling

Polyurethane Wheels for Load-Haul Dumpers in the Mining Industry

Polyurethane Wheels for Mining Monorail Hoists