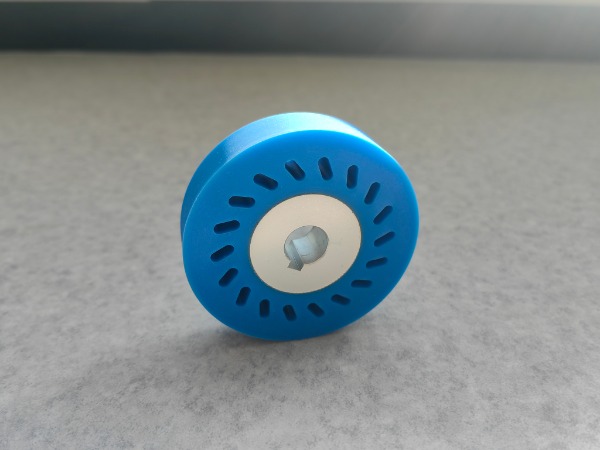

Keyway-mounted Polyurethane AGV Wheels

Keyway-mounted polyurethane AGV wheels deliver zero-slip precision, exceptional impact resistance, and superior durability for demanding automation in semiconductor, automotive, and heavy machinery applications.

Technical Information

Traditional hub mounting methods often face issues such as low torque transmission efficiency and installation position deviation under extreme operating conditions. Today, the adoption of keyway-mounted Vulkollan® polyurethane AGV wheels provides a revolutionary solution to these challenges. This unique design perfectly combines the precision of mechanical transmission with the durability of high-performance polyurethane material, setting a new standard for demanding industrial applications.

Core Advantages

1. Zero-Slip Precision Transmission

The keyway mounting design ensures absolute zero relative rotation between the wheel and the drive shaft through mechanical interlocking. Even under extreme conditions such as rapid acceleration, sudden braking, or heavy-load startups, it guarantees 100% torque transmission efficiency, completely eliminating the micro-slip phenomena that may occur with traditional press-fit methods.

2. Ultra-High Positioning Accuracy

The keyway structure provides irreplaceable angular positioning precision, ensuring that the installation position of each wheel is completely consistent. This is particularly important for multi-wheel AGV systems requiring synchronous control, effectively preventing the crabbing phenomenon caused by wheel angle deviations and enhancing the overall linear motion accuracy of the machine.

3. Exceptional Impact Resistance

The inherent excellent elasticity of Vulkollan® material, combined with the rigid connection of keyway mounting, forms a unique rigid-yet-flexible structure. This design effectively absorbs shocks caused by uneven ground surfaces while maintaining the rigidity of the transmission, making it particularly suitable for use in complex ground environments such as steel plate seams and track intersections.

4. Extreme Environmental Adaptability

Chemical Resistance: Vulkollan® offers excellent resistance to common industrial chemicals such as oil, lubricants, and weak acids or bases.

Wide Temperature Range Stability: Maintains stable physical properties within a temperature range of -30°C to +80°C.

Wear Life: Service life can be 3–5 times longer than that of ordinary polyurethane wheels.

Application Scenarios Precision Matching

Semiconductor and Electronics Manufacturing: In cleanroom environments, traditional lubricants may cause contamination. Keyway mounting requires no additional anti-loosening agents or locking adhesives. Combined with the low-dust characteristics of Vulkollan® material, it fully meets the requirements of ISO Class 5–6 cleanrooms.

Automotive Assembly Lines: When heavy-duty AGVs transport heavy components such as engines or body assemblies, keyway mounting ensures precise control of start-stop positions even under 3–5 ton loads, avoiding positioning errors caused by wheel slippage.

Aerospace Manufacturing: The transportation of large composite components requires extremely high motion stability. The excellent damping characteristics of Vulkollan® can reduce vibration transmission by over 90%, protecting sensitive components from damage during transportation.

Heavy Machinery Industry: In harsh environments with metal debris or welding spatter, the reliability of keyway connections far surpasses that of traditional methods. Even when the wheel surface wears to its limit, the transmission connection remains secure and reliable.

Customization Service Capabilities

We provide complete customized solutions:

Keyway Specifications: Can be customized to customer shaft standards, including rectangular keys, woodruff keys, and other specifications.

Hardness Range: Offers multiple hardness options from Shore A 85° to 98°.

Wheel Surface Design: Various traction surface designs, including flat surfaces, V-shaped surfaces, and special patterns.

Anti-Static Versions: Surface resistance of 10⁵–10⁸ Ω, meeting requirements for flammable and explosive environments.

Conclusion

Vulkollan® keyway-mounted AGV wheels provide a trustworthy solution for high-precision, high-reliability material handling. Whether in semiconductor cleanrooms, automotive production lines, or heavy manufacturing workshops, this innovative design ensures that your automated systems operate with maximum efficiency and reliability.

You have questions, we have answers. Contact us today. Our skilled customer service specialists can help you make the right choice in polyurethane applications.

Polyurethane Coated Wheels for FOUP SMIF Handlers

Polyurethane Tread on Steel Keyed Drive Wheels