-

WhatsApp: +86 19941574798

WhatsApp: +86 19941574798

-

sale06@kfqizhongji.com

sale06@kfqizhongji.com

Semiconductor Workshop Equipment

Semiconductor Overhead Hoist Transport (OHT) Travel Wheels

High-performance semiconductor OHT travel wheels with precision treads and durable cores. Designed for cleanroom transport, they ensure low particle emission, ESD safety, and long service life.

High-performance semiconductor OHT travel wheels with precision treads and durable cores. Designed for cleanroom transport, they ensure low particle emission, ESD safety, and long service life.

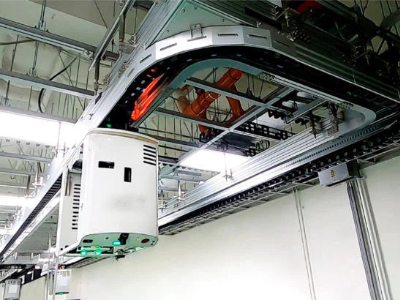

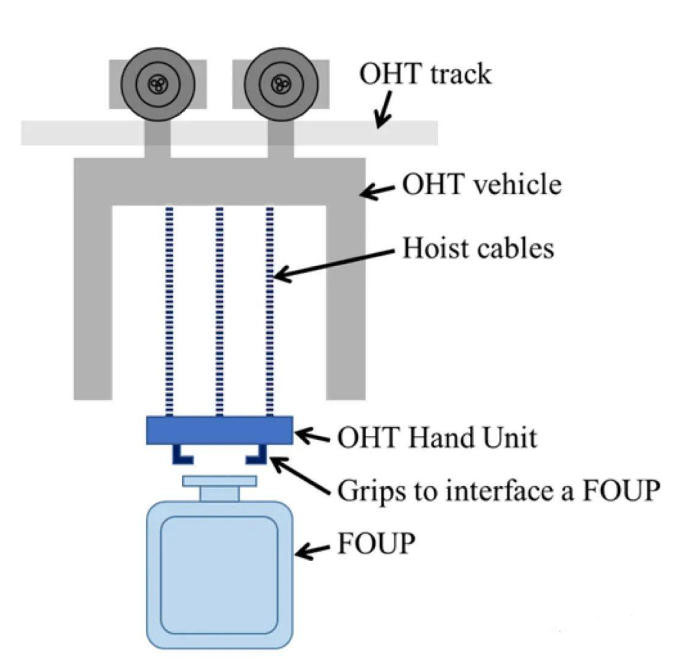

What is OHT?

OHT, or Overhead Hoist Transport, is an automated material handling system used in semiconductor fabrication plants (fabs) to transfer wafer pods (FOUPs) between processing tools. The OHT system consists of ceiling-mounted rails and self-propelled carriers, which travel above production equipment to save valuable floor space and maintain strict cleanroom airflow patterns.

A key part of these carriers is the travel wheel assembly, which ensures smooth, precise, and contamination-free movement.

Wheel tread materials

The tread is the outer rolling surface of the wheel, making direct contact with the rail. In semiconductor OHT systems, tread materials must minimize particle generation and resist wear from continuous operation. Common tread materials include:

Polyurethane (PU) – High wear resistance, low rolling resistance, quiet operation, and cleanroom-compatible due to minimal particle shedding.

Anti-static polyurethane – Prevents electrostatic discharge (ESD) that could damage sensitive semiconductor wafers.

High-performance engineering plastics (e.g., POM, PEEK) – Lightweight and low-friction, suitable for certain load and speed requirements.

Wheel core materials

The core supports the tread and transmits load from the axle. The core material choice affects wheel strength, weight, and dimensional stability:

Aluminum alloy – Lightweight, strong, and corrosion-resistant, commonly used for high-speed OHT operations.

304/316L Stainless steel – Higher load capacity, excellent dimensional stability, and resistance to deformation under continuous use.

Engineering plastics – Lightweight and corrosion-free, ideal for low-load carriers.

Key characteristics of OHT travel wheels

Low particle emission – Critical for maintaining ISO Class 1–3 cleanroom standards.

High-dimensional precision – Ensures stable tracking on OHT rails without vibration.

Wear and abrasion resistance – Extends service life in high-frequency production cycles.

ESD safety – Prevents electrostatic damage to semiconductor wafers.

Quiet and smooth operation – Minimizes noise and mechanical stress on the OHT carrier.

Applications

OHT travel wheels are widely used in:

Semiconductor fabs – Transporting FOUPs between lithography, etching, deposition, and metrology tools.

Flat-panel display production – Cleanroom transport systems for LCD and OLED production.

Pharmaceutical cleanrooms – Material movement with strict contamination control.

In semiconductor manufacturing, OHT travel wheels are more than just components—they are precision-engineered parts that directly impact production efficiency and product yield. Matching the right tread and core materials to the operating conditions ensures optimal performance, minimal downtime, and a longer service life.

Philson has its factory and equipment to provide cleanroom transportation equipment wheels made of the above materials. We have comprehensive design and production capabilities. Please get in touch with us for information and quotes.

Categories

Recent Cases

Recent Products

Recent Blogs

- How Do Polyurethane Wheels Compare To Metal Wheels

- Why Choose Injected Polyurethane (TPU) Wheels for Your Equipment

- Why Roller Coasters Use NDI Polyurethane Wheels

- How to Choose a Poly Wheels Manufacturer That Won't Fail

- Why Polyurethane is the Choice for Pallet Jack and Forklift Wheels

- Pallet Stacker Drive & Idler Wheels for Automated Warehouses

- Mold-on Polyurethane Wheels

- Analysis of the Causes of Cleanroom Stacker Polyurethane Wheel

- Why Are NDI Drive Rollers the Premier Choice for Pallets

- Polyurethane Wheels in Mining

Semiconductor Wafer Transport Urethane Wheels

LCD Panel Cleanroom Polyurethane Drive Wheel