Aluminum Polyurethane Rubber Wheels

Aluminum Polyurethane Rubber Wheels combine the strength of an aluminum core with the vibration and noise-reducing properties of a polyurethane rubber coating for lightweight durability, precision handling, and floor protection.

Technical Information

Aluminum polyurethane rubber wheels are the first choice for industries that seek lightweight durability, precision handling, and floor protection. Combining the strength of an aluminum core with the vibration and noise-reducing properties of a polyurethane rubber coating, these wheels excel in dynamic environments. Here are their types, highlights, and examples.

Wheel types: Design meets function

Aluminum polyurethane rubber wheels are designed for specific uses. Here is a breakdown of common types:

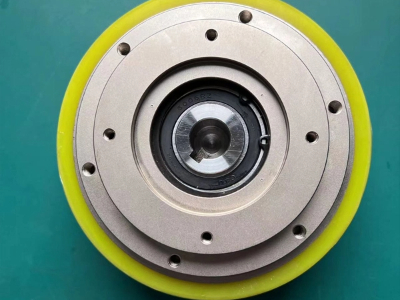

Driving wheels:

Drive wheels are designed for electric or steering systems and have integrated bearings or swivel mechanisms for precise control. Ideal for automated guided vehicles (AGVs), robots, or adjustable conveyor systems.

Driven wheels:

These wheels are used to transmit power and are commonly used in material handling equipment such as forklifts, tractors, or assembly line machinery.

Friction wheels:

Use surface grip to transmit motion without the need for gears or teeth—ideal for applications such as manual carts, cleanroom packaging lines, etc.

Conveyor wheels:

Designed for seamless integration into conveyor systems. Its smooth-rolling polyurethane tread minimizes drag, ensuring efficient transport of goods in a warehouse or production facility.

Guide wheels:

Provide directional stability in track-based systems. Commonly used in sliding doors, industrial automation, or guided vehicle systems to prevent deviation.

Key features of aluminum polyurethane rubber wheels

These wheels stand out due to their unique material synergy:

Lightweight strength:

The aluminum core reduces the overall weight of the equipment while maintaining structural integrity, improving the energy efficiency of electric systems.

Shock and vibration absorption:

The polyurethane rubber absorbs impacts, protecting cargo and equipment from damage on uneven surfaces.

Scratch-resistant, protective flooring:

The rubber coating prevents scratches and abrasions on delicate flooring such as epoxy, hardwood, or tile.

Chemical and moisture resistant:

Resistant to oils, solvents, and moisture, suitable for factory, laboratory, or outdoor use.

Quiet operation:

Quieter than metal or hard plastic wheels, perfect for hospitals, offices, or noise-sensitive environments.

High load capacity:

The aluminum core with reinforced polyurethane can handle dynamic loads up to 1,000+ pounds, depending on size and design.

| Polyurethane on aluminum wheels | |

| Wheel size | Load |

| 4" x 2" | 800lb |

| 5" x 2" | 900lb |

| 6" x 2" | 1200lb |

| 8" x 2" | 1250lb |

Aluminum polyurethane-covered wheels are a versatile solution that combines lightweight with strength, flexibility, and floor protection. Whether you’re automating a factory, navigating a hospital hallway, or transporting cargo outdoors, choosing the right type—active, drive, conveyor, or guide—ensures optimal performance. Prioritize load capacity, tread design, and environmental resistance to maximize value and durability.

You have questions, we have answers. Contact us today. Our skilled customer service specialists can help you make the right choice in polyurethane applications.

Polyurethane-Covered Bearing Wheels

Heavy-Duty Cast Iron Polyurethane Wheels