-

WhatsApp: +86 19941574798

WhatsApp: +86 19941574798

-

sale06@kfqizhongji.com

sale06@kfqizhongji.com

Special Equipment

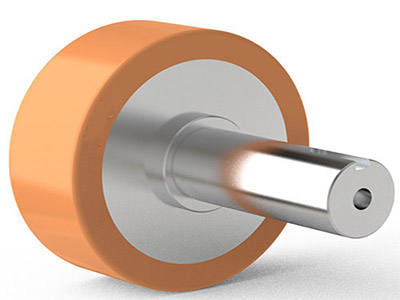

Textile Machinery Polyurethane-Coated Wheels

Textile machinery polyurethane-coated wheels are widely used in spinning machines, looms, dyeing and finishing equipment, etc., due to their excellent wear resistance, high load-bearing capacity, low noise, and stability.

Textile machinery polyurethane-coated wheels are widely used in various textile equipment, including spinning machines, looms, dyeing and finishing equipment, etc., due to their excellent wear resistance, high load-bearing capacity, low noise, and stability. Since textile machinery runs at a high speed and has extremely high requirements for stability and continuity, the selection of polyurethane wheels with excellent characteristics can significantly improve production efficiency and extend the service life of the equipment.

Features of polyurethane-coated wheels for textile machinery

• High wear resistance and extended service life: Textile machinery is in high-speed operation for a long time, and the wheels need to frequently contact the guide rails or conveyor belts, resulting in great friction loss. Polyurethane wheels have excellent wear resistance, which can effectively resist the wear caused by high-speed friction, extend the service life of the wheels, and thus reduce equipment maintenance costs.

• Maintain stability under high-speed operation: Textile machinery needs to run at high speed for a long time. Heavy-duty polyurethane wheels have extremely high dynamic balancing performance, which can maintain stability under high-speed conditions, prevent wheel shaking or deviation, effectively avoid textile line breakage or equipment damage, and improve production efficiency.

• Excellent corrosion resistance and chemical resistance: Textile machinery is often in a humid environment or in contact with chemical additives. Polyurethane wheels have excellent hydrolysis resistance, grease resistance, and chemical corrosion resistance. They can effectively resist the erosion of various chemicals and keep the wheels in good condition.

• High load-bearing capacity to meet heavy load requirements: Textile equipment often has a large load. Poly wheels have extremely high load-bearing capacity and can maintain deformation and collapse under heavy loads, ensuring long-term stable operation of the equipment.

Application scenarios of polyurethane wheels for textile machinery

• Spinning machine guide wheels and tension wheels: Spinning machines are one of the core equipment in textile production. Guide wheels and tension wheels control the tension and balance of fibers during the spinning process. Polyurethane wheels can maintain uniform tension at high speeds without slipping, thereby ensuring the quality and output of spinning.

• Loom guide wheels and drive wheels: The guide wheels and drive wheels of looms need to run stably for a long time and at high speeds, while avoiding fiber breakage or thread breakage. Polyurethane wheels have extremely high wear resistance and stability, and can maintain stable operation under high load conditions to ensure a smooth weaving process.

• Guide wheels and conveyor wheels for printing and dyeing equipment: Guide wheels and conveyor wheels in printing and dyeing equipment are required to be corrosion-resistant and high-temperature resistant. Polyurethane wheels can maintain stable performance when exposed to chemical dyes and high-temperature environments, without deformation or chemical reactions, ensuring the uniformity and stability of fabrics during the dyeing and finishing process.

• Textile logistics conveying system: The material conveying system in a textile factory needs to frequently move a large amount of fabric, yarn, or finished products. Polyurethane conveyor wheels have high load capacity and low rolling resistance, which can easily achieve smooth and fast material transportation and improve logistics efficiency.

Selection and application of polyurethane-coating wheels with different hardness

• Low hardness (Shore A 70-80): Suitable for light-load equipment, with good elasticity and buffering performance. Mainly used in tension wheels, guide wheels, and light textile equipment.

• Medium hardness (Shore A 85-90): Suitable for medium load and medium-high speed operation environment. Mainly used in equipment that needs to run for a long time, such as loom drive wheels and printing and dyeing equipment conveyor wheels.

• High hardness (Shore D 50-60): Suitable for heavy-load, high-speed equipment. Mainly used in spinning machine guide wheels, heavy-duty polyurethane wheels in logistics conveying systems, and high-speed printing and dyeing equipment.

Wheel customization and installation optimization

According to the customer's equipment type and operation requirements, we can provide personalized wheel size, hardness, thickness, and other customization services, and provide professional installation optimization suggestions to ensure that the wheel and equipment are perfectly matched.

Whether in high-speed spinning machines, long-running looms, or heavy-load logistics conveying systems, Philson polyurethane wheels can provide reliable guarantees for the textile industry and help companies achieve efficient operation.

Categories

Recent Cases

Recent Products

Recent Blogs

- How Do Polyurethane Wheels Compare To Metal Wheels

- Why Choose Injected Polyurethane (TPU) Wheels for Your Equipment

- Why Roller Coasters Use NDI Polyurethane Wheels

- How to Choose a Poly Wheels Manufacturer That Won't Fail

- Why Polyurethane is the Choice for Pallet Jack and Forklift Wheels

- Pallet Stacker Drive & Idler Wheels for Automated Warehouses

- Mold-on Polyurethane Wheels

- Analysis of the Causes of Cleanroom Stacker Polyurethane Wheel

- Why Are NDI Drive Rollers the Premier Choice for Pallets

- Polyurethane Wheels in Mining

none

Polyurethane-Coated Conveyor Rollers