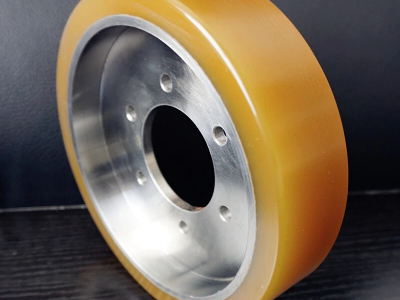

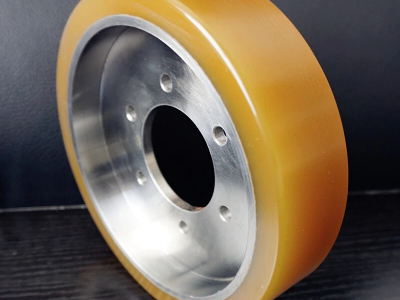

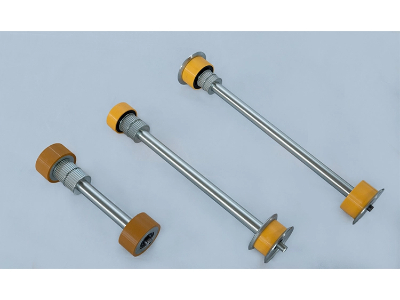

Polyurethane Wheels Relining / Recoating

Relining or recoating polyurethane wheels extends service life, lowers costs, and reuses wheel cores. Philson ensures durability with premium PU materials, precise processing, and strict quality control.

Technical Information

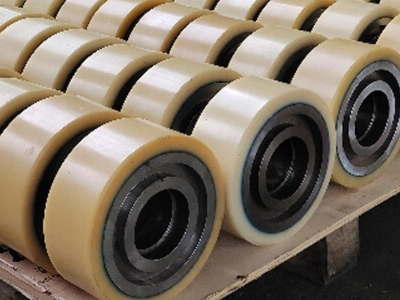

Polyurethane wheels are widely used in industries requiring heavy-duty load capacity, wear resistance, and long service life. Over time, however, the outer PU layer may wear down while the wheel core remains intact. In such cases, relining or recoating polyurethane wheels is an economical and sustainable solution compared to full replacement.

Advantages of relining or recoating

• Cost savings – refurbishing a wheel is often 30–50% less expensive than purchasing a new wheel.

• Sustainability – reusing wheel cores reduces waste and lowers material consumption.

• Extended service life – with high-quality recoating, a refurbished wheel can perform as well as a new one.

• Customization – relined wheels can be poured with specific polyurethane hardness, colors, or properties (e.g., anti-static, oil-resistant) tailored to the application.

Key considerations in the recoating or relining process

While recoating provides many benefits, several issues must be carefully addressed to ensure quality and durability:

• Surface preparation of the core – any debris, oil, or rust must be removed, as they can prevent strong adhesion between the wheel core and new polyurethane layer.

• Bonding failures – poorly treated cores may lead to coating shedding or delamination under heavy loads.

• Dimensional accuracy – improper pouring or machining can result in uneven wheel surfaces, affecting performance.

• Material quality – low-grade polyurethane may reduce abrasion resistance, leading to premature wear.

Philson’s quality assurance

Philson ensures every relined wheel meets strict performance standards through:

• Premium polyurethane materials – high-grade prepolymers and curatives provide superior wear resistance, chemical stability, and load capacity.

• Advanced processing technology – wheel cores are sandblasted, cleaned, and primed with specialized bonding agents to guarantee strong adhesion.

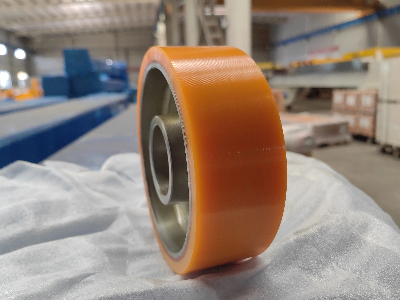

• Controlled recoating process – polyurethane is precisely cast or re-poured using advanced molds and curing systems, ensuring dimensional accuracy and uniform coating thickness.

• Post-processing and testing – each wheel undergoes precision machining, hardness testing, and load-bearing inspection to confirm compliance with specifications.

Step-by-step recoating or relining process

• Inspection – evaluate wheel core condition and determine if refurbishment is feasible.

• Core preparation – remove old polyurethane, clean and sandblast the core, and apply bonding agent.

• Polyurethane pouring/recoating – re-pour high-performance PU onto the prepared core.

• Curing – heat treatment ensures full cross-linking of polyurethane molecules for maximum strength.

• Finishing – machining for final dimensions, surface polishing, and quality checks.

Relining or recoating polyurethane wheels is a smart choice for industries looking to balance performance, cost-efficiency, and sustainability. By reusing wheel cores and applying premium polyurethane coatings, companies can extend the lifespan of their equipment and reduce operating costs. With advanced facilities, skilled engineers, and high-quality materials, Philson provides reliable polyurethane wheel refurbishment services that deliver new-wheel performance at a fraction of the cost.

You have questions, we have answers. Contact us today. Our skilled customer service specialists can help you make the right choice in polyurethane applications.

PU Wheels and Casters for Aviation and Aerospace

Polyurethane Printing Rollers