How do you maintain polyurethane wheel longevity?

Discover strategies to extend polyurethane industrial wheel lifespan through proper material selection, preventive maintenance, and predictive monitoring. Learn how to prevent wear, reduce downtime, and maximize ROI in demanding industrial environments.

Technical Information

Advanced material selection and preventive maintenance protocols maximize operational efficiency in demanding industrial environments

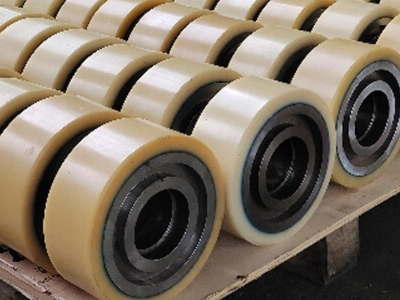

Polyurethane industrial wheels continue to be the preferred choice for material handling equipment across manufacturing, logistics, and aerospace sectors, valued for their exceptional load-bearing capacity, abrasion resistance, and noise reduction properties. However, industry experts emphasize that maximizing their service life requires implementing comprehensive maintenance strategies and operational protocols.

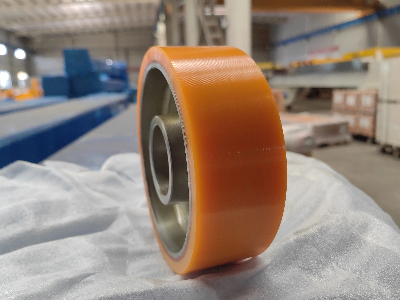

Application-Specific Selection Critical for Longevity

Technical specialists highlight the importance of matching wheel specifications to operational requirements. "Selecting wheels with load capacities exceeding maximum expected loads by at least 25% prevents premature failure," states Dr. Elena Rodriguez, senior engineer at Advanced Material Solutions. Equally crucial is durometer selection—softer compounds (85A) for shock absorption in uneven environments, while harder formulations (95A+) excel in high-abrasion applications. Environmental compatibility must also be considered, with oil-resistant, temperature-stable, and anti-static variants now available for specialized applications.

Proactive Maintenance Protocol Implementation

Leading facilities have established systematic inspection routines that significantly extend wheel service intervals. Regular diameter measurements identifying wear beyond 10-15% of original specifications trigger replacement before failure occurs. Comprehensive checks for polyurethane separation from metal cores, cracking, and bearing degradation are conducted monthly in high-utilization environments.

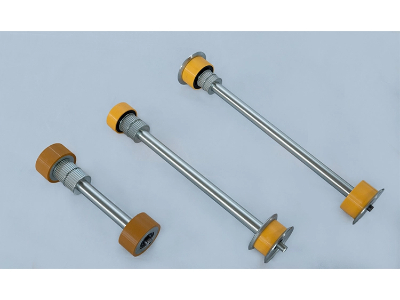

"Proper installation remains the most overlooked factor," notes Michael Chen, maintenance director at Global Industrial Solutions. "Correct torque application during mounting and verifying parallel alignment to guiding surfaces prevents asymmetric wear patterns that reduce service life by up to 40%."

Operational Excellence and Environmental Protection

Progressive operations teams have implemented load distribution systems that prevent individual wheel overloading, while operator training programs emphasize avoiding impact damage from debris and surface irregularities. Facilities operating in challenging environments report success with protective wheel covers and specialized track cleaning systems that remove abrasive contaminants.

Storage protocols have likewise evolved, with temperature-controlled environments and vertical storage configurations preventing material deformation during downtime. Immediate cleaning procedures for chemical exposure have become standard in facilities handling oils, solvents, or acidic compounds.

Industry-Wide Shift to Predictive Maintenance

The integration of IoT monitoring systems represents the latest advancement, with embedded sensors tracking wear patterns, temperature fluctuations, and load variations. "This data-driven approach enables replacement before failure, reducing unplanned downtime by up to 60%," confirms Sarah Wilkinson, CEO of Industrial Analytics Group.

As material science advances, new polyurethane formulations offering enhanced durability and specialized properties continue to emerge. However, industry consensus confirms that proper selection, installation, and maintenance practices remain the fundamental factors in maximizing the operational lifespan and return on investment for polyurethane industrial wheel systems.

Manufacturers and maintenance professionals seeking to optimize polyurethane wheel performance should consult ISO 10110-23 standards and manufacturer-specific technical data sheets for application-specific guidance.

Contact our expert team now for free technical consultation and project proposals!

You have questions, we have answers. Contact us today. Our skilled customer service specialists can help you make the right choice in polyurethane applications.

Precision Wheels for Semiconductor Stocker Equipment

none