-

WhatsApp: +86 19941574798

WhatsApp: +86 19941574798

-

sale06@kfqizhongji.com

sale06@kfqizhongji.com

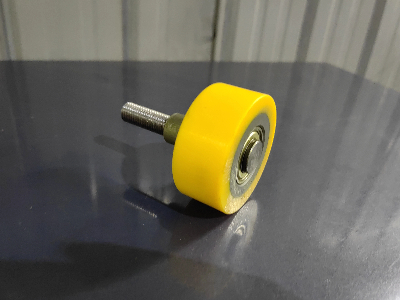

Amusement Equipment Wheels

Suspended Roller Coaster Wheels in Amusement Park

Suspension roller coaster wheels feature iron or steel cores with 98±1 hardness polyurethane tread, bonded for durability. High-speed, wear-resistant, high-load, quiet, and safe—ideal for amusement parks and ride manufacturers.

In modern large-scale amusement parks, suspended roller coasters are highly sought after for their thrilling ride experience. As key components for operational safety and stability, roller coaster wheels and their associated wheel sets (side wheels and bottom wheels) play a vital role in the entire system.

Application case: Discovery theme park

Take the example of a suspended roller coaster at a discovery theme park:

Train configuration: Each train has 10 rows of cars, plus a final row of counterweights for a total of 11 rows;

Wheel configuration: Each car is equipped with 4 running wheels, 4 side wheels, and 2 bottom wheels;

Total vehicle configuration: 44 running wheels, 44 side wheels, and 22 bottom wheels, ensuring stability and safety at high speeds.

Technical requirements and performance guarantee

To ensure safe operation of roller coasters under high speeds, high impact, and complex track conditions, wheels must meet the following technical standards:

Strong bonding: The wheel core and polyurethane layer are tightly bonded to prevent debonding during long-term use.

Sealing protection: The wheel core is sealed with a seal that prevents oil leakage, ensuring a stable lubrication system.

Flexible processing: The mold draft angle is customizable by the manufacturer to ensure process and structural reliability.

Precision machining: The coaxiality of each hole meets a geometric tolerance of grade 7, and sharp corners not marked with chamfers are rounded.

High-hardness material: The polyurethane tread has a shore hardness of 98±1, ensuring high wear resistance and load-bearing capacity.

Product advantages

Wear-resistant and impact-resistant: Polyurethane material withstands long-term, high-speed friction, significantly extending wheel life.

Smooth operation: High-precision manufacturing ensures a tight fit between the wheel and track, reducing vibration and noise.

Safe and reliable: Flame-retardant and fatigue-resistant, ensuring stable operation even under extreme conditions.

Customized service: Specifications, hardness, and structure can be customized based on the specific roller coaster model and track parameters.

Application scenarios

Suspended roller coaster wheels are not only suitable for roller coasters in large theme parks, but can also be used in other high-intensity suspended amusement rides such as flying roller coasters, inverted roller coasters, and high-speed gliding trains, fully ensuring a pleasant visitor experience and long-term operation.

Why Philson is qualified?

Philson has a comprehensive production and testing system that meets the stringent technical requirements of suspended roller coaster wheels.

High-precision wheel core machining equipment ensures hole coaxiality and geometric tolerances meet class 7 standards, and chamfers can be added according to customer requirements.

Advanced polyurethane casting and reinforcement technology ensures a fast bond between the wheel core and tread, preventing debonding. The metal wheel core is cleaned, polished, and sandblasted to enhance cleanliness and friction, further ensuring the wheel's lifespan and safety.

The wheel core is embedded in the sealing ring, ensuring zero oil leakage and stable operation of the lubrication system.

A shore hardness tester and wear resistance testing equipment precisely control the polyurethane tread hardness to 98±1.

High load-bearing capacity and wear resistance ensure the wheels remain safe and reliable in high-speed, high-impact, and complex track environments.

Philson polyurethane amusement equipment wheels utilize professional craftsmanship and rigorous testing to ensure every high-speed ride is safe and secure, ensuring a longer-lasting enjoyment.

Customization is welcome!

Categories

Recent Cases

Recent Products

Recent Blogs

- How Do Polyurethane Wheels Compare To Metal Wheels

- Why Choose Injected Polyurethane (TPU) Wheels for Your Equipment

- Why Roller Coasters Use NDI Polyurethane Wheels

- How to Choose a Poly Wheels Manufacturer That Won't Fail

- Why Polyurethane is the Choice for Pallet Jack and Forklift Wheels

- Pallet Stacker Drive & Idler Wheels for Automated Warehouses

- Mold-on Polyurethane Wheels

- Analysis of the Causes of Cleanroom Stacker Polyurethane Wheel

- Why Are NDI Drive Rollers the Premier Choice for Pallets

- Polyurethane Wheels in Mining

Polyurethane Wheels Elevate Amusement Ride Performance

High Wear-Resistant Polyurethane Wheels for Roller Coasters