- WhatsApp: +86 19941574798

- sale06@kfqizhongji.com

How To Choose Industrial Wheels For Amusement Rides

Learn how to select the right industrial wheels for your amusement rides Understand the functions of different wheel types compare material properties and ensure compliance with safety standards for optimal operation

The industrial wheels used in amusement rides are core components for their safe and stable operation. These wheels need to withstand high-intensity loads, impacts, and complex working conditions, and are specially designed and selected based on their specific functions.

1. Four Major Roles: The Distinct Functions of Amusement Ride Wheels

Within large amusement rides, different wheels play distinctly different roles:

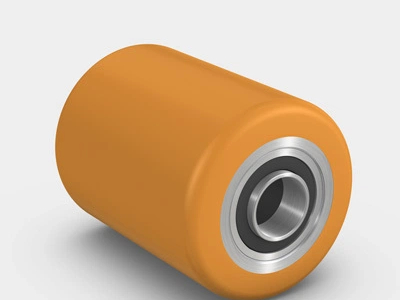

Load Wheels: These are the primary load-bearers, acting like the load-bearing walls of a building, directly supporting the entire weight of the equipment and all its passengers. Whether it's a roller coaster car or a Ferris wheel cabin, stable operation relies on the exceptional load capacity and structural strength of the load wheels.

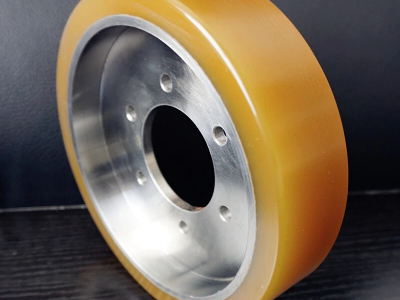

Guide Wheels / Side Wheels: How is derailment prevented during high-speed turns and on complex tracks? The answer lies in guide wheels. Typically installed in pairs on the sides of the vehicle, they tightly "clamp" the sides of the track. By withstanding significant horizontal lateral forces, they ensure the vehicle always follows the intended path precisely, serving as the first line of safety.

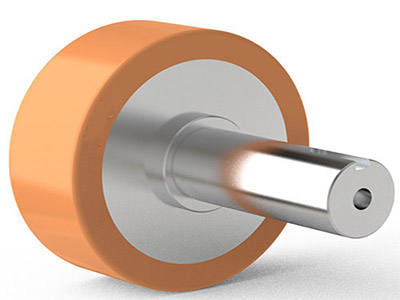

Drive Wheels / Friction Wheels: Some equipment can accelerate and rotate smoothly without chains or gears. This is made possible by drive wheels. Driven by motors, they transmit power to the vehicle using friction against the track or platform surface. Similar to automotive drive wheels, they require extremely high grip and wear resistance.

Idler Wheels / Casters: For equipment that requires movement and steering (such as movable stages or service carts), swivel idler wheels provide unparalleled flexibility. They allow heavy equipment to be moved easily and are indispensable assistants for behind-the-scenes operations.

2. The Contest of Materials: Ensuring Performance and Safety

The "soul" of a wheel lies in its material. Different materials define their performance limits:

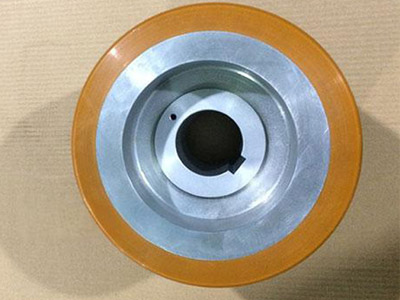

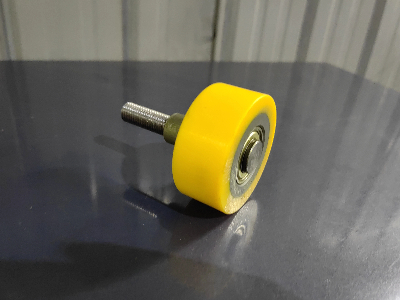

Polyurethane: This is currently the most mainstream material in amusement rides. It perfectly balances three major advantages: high load capacity, high elasticity, and superior wear resistance. Its shock absorption and noise reduction significantly enhance ride comfort, while its wear resistance – several times that of rubber – greatly extends maintenance cycles. It is the ideal choice for load wheels and drive wheels.

Nylon (Polyamide): Known for its high strength, high hardness, and excellent wear resistance. It performs exceptionally well under extremely high loads, but its damping and quietness are slightly inferior to polyurethane. It is often used in load-bearing positions requiring extreme rigidity.

Rubber: Rubber provides the ultimate in shock absorption and quiet operation, delivering an unrivalled smooth experience. However, its wear resistance and anti-aging capabilities are relatively weak. It is commonly used in low-speed equipment where comfort is paramount.

Metal (Cast Steel / Cast Iron): These represent the peak of load capacity and wear resistance, but at the cost of zero elasticity, high noise levels, and heavy weight. They are used only in specific industrial scenarios involving extreme loads and low speeds, and are gradually being replaced by high-performance engineering plastics in modern high-end amusement rides.

3. Beyond the Ordinary: Stringent Selection Criteria

Selecting wheels for amusement rides is a rigorous engineering decision-making process that must consider multiple extreme factors:

Safety Factor is Paramount: The wheel's rated load capacity must far exceed its actual load. Typically, a safety factor of 1.5 or higher is required to cope with the immense impact forces from sudden starts and stops.

Challenges of Dynamic Conditions: High-speed operation (e.g., roller coasters exceeding 100 km/h) generates tremendous centrifugal force, vibration, and heat, demanding wheels with extremely high structural integrity, balance, and heat resistance.

Environmental Durability: Wheels for outdoor facilities need to withstand sun, rain, UV degradation, and temperature variations. Their material must possess good environmental stability.

Conclusion

It is these inconspicuous wheels, with their superior performance and reliable safety guarantees, that support the wonderful journey of the ride. They are not just mechanical components, but also the solid foundation safeguarding joy.

For more detailed product information or technical support, please feel free to contact us at any time!

Categories

Recent Cases

Recent Products

Recent Blogs

- Polyurethane Forklift Wheels for Warehousing Pallet Handling

- What industries benefit most from using polyurethane industrial wheels?

- How do polyurethane wheels compare to metal wheels?

- Applications of Polyurethane Wheels in Mining

- How do you maintain polyurethane wheel longevity?

- How To Choose Industrial Wheels For Amusement Rides

- Polyurethane Wheels Noise Reduction 70 Percent Quieter

- Polyurethane Coated Wheels Superior Performance Advantages

- Advantages of Heavy-Duty Polyurethane Cast Iron Wheels

- Why Are NDI Drive Rollers the Premier Choice for Pallets?

Polyurethane Wheels Noise Reduction 70 Percent Quieter

How do you maintain polyurethane wheel longevity?