-

WhatsApp: +86 19941574798

WhatsApp: +86 19941574798

-

sale06@kfqizhongji.com

sale06@kfqizhongji.com

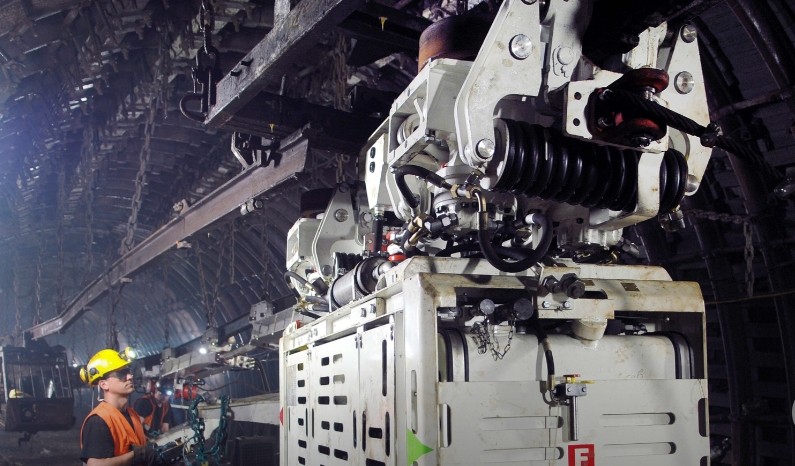

Mining Monorail Hoisting Equipment

Coal Mine Monorail Drive Wheels

Philson polyurethane monorail drive wheels, available in sizes 340×95, 300×100, 315×100, 350×95, 400×100, 450×97, 340×100 and more. Durable, low-heat and wear-resistant, ideal for coal mining, tunneling and mineral transport.

In underground coal mine transportation systems, monorail trains are widely used to transport personnel and materials, and are crucial for efficient mine operations. The drive wheel, as a core component, directly determines transportation efficiency, safety, and operating costs.

Wheel structural features

Coal mine monorail drive wheels typically consist of three main components:

High-strength wheel core: Utilizes high-quality metal materials to ensure structural strength and load-bearing capacity.

Polyurethane tread: Offers excellent wear and impact resistance, making it suitable for high-dust and complex geological environments.

Advanced bonding technology, including polyurethane casting and precision craftsmanship, ensures a secure bond between the tread and the wheel core, preventing delamination.

Wheel advantages

High slope adaptability: A single wheel can operate stably on slopes up to 35° and can transport loads of up to 4-5 tons (customization available).

Low heat generation and zero emissions: Polyurethane drive wheels maintain low heat generation even under high loads, reducing the need for cooling and fresh air.

Reduced energy costs: Mine ventilation energy consumption accounts for approximately 30% of total energy costs, and low-heat wheels contribute to energy savings and cost reductions.

Wear and dust resistance: Maintains excellent performance in dusty and complex mines, extending service life.

Application scenarios

Polyurethane drive wheels for monorail transport systems are widely used in:

Mineral mining

Coal transportation

Tunneling

Personnel and material transport

Globally, hard rock mining in South Africa, longwall mining in Poland in Europe, and mine transportation in Russia are key applications for Philson products.

Product specifications and compatibility

Philson offers a variety of custom specifications and thicknesses, including 340×95, 340×100, 300×80, 315×100, 350×95, 400×100, and 450×97. These products are compatible with electric and diesel monorails from brands such as Scharf, Ferrite, Farmul, Baker, Euroka, and Statif.

Philson's manufacturing capabilities

As a global polyurethane product manufacturer, Philson offers full-process production and testing capabilities:

Polyurethane casting and metal wheel core precision machining

Polyurethane wheel blank finishing

Negative detection, hardness testing, and quality control

Comprehensive design, production, delivery, and after-sales support

With its mature manufacturing system and rigorous testing standards, Philson provides highly reliable polyurethane drive wheel solutions for mine transportation, helping customers maintain efficient, safe, and sustainable operations in harsh environments.

Contact Philson for customized coal mining equipment wheel solutions!

Categories

Recent Cases

Recent Products

Recent Blogs

- How Do Polyurethane Wheels Compare To Metal Wheels

- Why Choose Injected Polyurethane (TPU) Wheels for Your Equipment

- Why Roller Coasters Use NDI Polyurethane Wheels

- How to Choose a Poly Wheels Manufacturer That Won't Fail

- Why Polyurethane is the Choice for Pallet Jack and Forklift Wheels

- Pallet Stacker Drive & Idler Wheels for Automated Warehouses

- Mold-on Polyurethane Wheels

- Analysis of the Causes of Cleanroom Stacker Polyurethane Wheel

- Why Are NDI Drive Rollers the Premier Choice for Pallets

- Polyurethane Wheels in Mining

none

Mining Anti-Static Cast Polyurethane Wheel