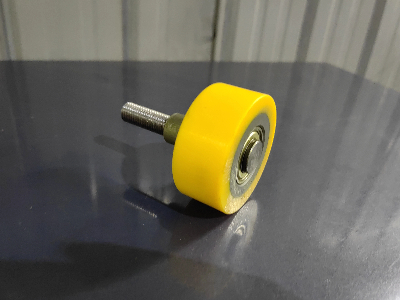

Polyurethane Printing Rollers

Philson supplies durable polyurethane printing rollers with excellent wear, chemical resistance, and precise ink transfer. Custom sizes, hardness, and recoating services meet diverse printing industry needs.

Technical Information

In the printing industry, rollers play a decisive role in ensuring high-quality, efficient, and consistent output. Polyurethane printing rollers have become the preferred choice for modern printing applications due to their superior material properties and adaptability.

Characteristics of polyurethane

Polyurethane (PU) combines the elasticity of rubber with the strength of plastics, offering:

Excellent wear resistance – significantly longer service life compared to traditional rubber rollers.

High load-bearing capacity – stable performance under continuous high-pressure printing.

Superior chemical resistance – withstands inks, solvents, oils, and cleaning agents commonly used in printing processes.

Controlled hardness range (Shore A 20–D 75) – customizable to meet specific roller hardness requirements.

Dimensional stability – maintains precision under heat, load, and continuous operation.

Advantages in the printing industry

The printing industry demands rollers that guarantee uniform ink transfer, precise alignment, and minimal downtime. Polyurethane rollers outperform conventional options by offering:

Smooth ink distribution without streaking or blotting.

Low compression set, preventing deformation during long print runs.

Resistance to swelling and degradation from printing oils and solvents.

Reduced maintenance frequency, lowering overall operational costs.

Quiet, vibration-free operation, enhancing printing accuracy.

Philson’s customizable poly rollers

Philson is a trusted printing roller supplier, specializing in high-performance polyurethane rollers tailored to the unique needs of printing presses. With advanced manufacturing equipment and over a decade of experience, we offer:

Custom roller dimensions and hardness to match specific press requirements.

Oil-resistant and solvent-resistant PU formulations for long-lasting performance.

Precision machining to ensure perfect surface finish and concentricity.

Short lead times and competitive pricing, supported by in-house design and production.

Relining and recoating services to refurbish used rollers and extend service life.

Whether you need oil-based polyurethane printing rollers, custom poly rollers, or high-durability solutions for continuous printing operations, Philson delivers products engineered for reliability and performance. Our polyurethane rollers provide the precision, resilience, and customization that the printing industry demands.

You have questions, we have answers. Contact us today. Our skilled customer service specialists can help you make the right choice in polyurethane applications.

Polyurethane Wheel Relining for Cost-Effective Industrial Performance

Laboratory AGV Polyurethane Drive Wheel