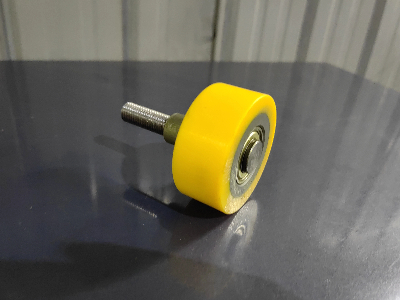

Laboratory AGV Polyurethane Drive Wheel

Laboratory AGV polyurethane drive wheels offer heavy load capacity, low dust, vibration isolation, and quiet operation, ensuring precise, clean, and reliable handling of sensitive optical and scientific equipment.

Technical Information

In laboratory automated handling systems, the efficient operation of AGVs (automated guided vehicles) depends on a core component—the drive wheel. For handling precision optomechanical instruments and optical components, polyurethane drive wheels with a single wheel load capacity of 2 tons, a diameter of approximately 350 mm, and an adaptable speed of 20 m/min are the preferred choice due to their precise adaptability. The following article provides an efficient analysis of their core advantages, applicable laboratory types, recommended technical parameters, and selection considerations.

Core advantages

• Stable transport: Polyurethane material has excellent vibration absorption properties, effectively isolating floor vibrations and preventing damage to delicate optical components and instruments during handling.

• Precise positioning: Combined with encoders and control systems, it achieves millimeter-level docking accuracy, meeting the demanding requirements of automated experimental processes.

• Cleanliness assurance: Low dust generation and anti-static properties prevent contamination of optical surfaces and interference with precision electronic equipment.

• Quiet operation: Low noise (<60db) and low vibration maintain a quiet laboratory environment.

• Protective performance: Does not damage epoxy resin floors, protecting expensive laboratory floors.

• Laboratory environment compatibility: Polyurethane drive wheels are chemically stable and resistant to corrosion from alcohol, acids, and alkalis.

• Customization capabilities: Performance can be optimized by adjusting the formula, such as increasing hardness to accommodate heavy loads or adjusting the material to accommodate specific temperature environments.

Applicable laboratory types

• Precision optoelectronics laboratory

Recommendations: Strong load capacity (2 tons per wheel) and excellent vibration isolation

Typical applications: Transporting heavy equipment such as large optical platforms and laser emission systems

• Optical component laboratory

Recommendations: Low dust generation and anti-static properties

Typical applications: Production and testing of high-precision optical components such as lenses and prisms

• Special requirements laboratory

Biomedical: Transporting large bioreactors requires cleanliness and quiet operation

Microelectronics research: Anti-static requirements to avoid interference with sensitive components

Aerospace: Transporting large composite components requires smooth and impact-free operation

Selection considerations

Key considerations when choosing a polyurethane drive wheel:

• Mounting interface: Ensures a perfect fit with the AGV drive motor output shaft.

• Encapsulation process: A two-component casting process is selected to ensure resistance to peeling under high loads.

• Customization: Formula adjustments can be made to meet specific environmental requirements (such as low-temperature resistance and resistance to specific chemicals).

Laboratory AGV polyurethane drive wheels are critical components for handling precision equipment. Their 2-ton single-wheel load capacity, excellent vibration resistance, and cleanliness make them ideal for demanding environments such as optomechanical and optical component labs. Proper selection and configuration not only improve handling efficiency but also provide crucial protection for valuable precision instruments.

You have questions, we have answers. Contact us today. Our skilled customer service specialists can help you make the right choice in polyurethane applications.

Polyurethane Printing Rollers

Polyurethane Wheels for Amusement Rides