-

WhatsApp: +86 19941574798

WhatsApp: +86 19941574798

-

sale06@kfqizhongji.com

sale06@kfqizhongji.com

Special Equipment

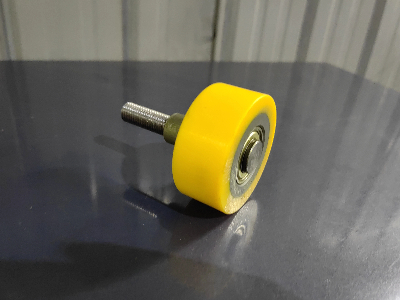

Medical-Grade Polyurethane Coated Wheels for CT/MRI

Medical-grade polyurethane coated wheels offer anti-interference, high cleanliness & stability. Ideal for CT/MRI platforms, surgical robots & testing instruments—customizable solutions.

With its customized material properties and structural design, polyurethane coated wheels can accurately meet the strict requirements of medical equipment for "low interference, high cleanliness, and strong stability". They have become core components of key medical devices such as CT/MRI auxiliary platforms, surgical robots, and testing instruments, fully empowering medical scenarios from mobile safety to transmission accuracy.

1. CT & MRI Auxiliary Mobile Platforms: Dual Advantages of Polyurethane Coated Wheels – "Anti-Interference + Stable Movement"

In medical scenarios, CT and MRI equipment have extremely high requirements for magnetic field stability and electrostatic control to avoid interfering with imaging accuracy or damaging electronic components. Polyurethane coated wheels, through material and process design, have become the exclusive adaptive wheels for this scenario:

Full Polyurethane Coating to Eliminate Magnetic Interference: The wheel body is fully coated with 100% polyurethane material (without any metal inserts or frames), fundamentally avoiding magnetic field distortion caused by metal parts. This ensures no deviation in CT/MRI scanning images and guarantees diagnostic accuracy.

Anti-Static Coating Layer to Protect Electronic Components: The surface of polyurethane coated wheels undergoes anti-static treatment, with a resistance value controlled between 10⁶-10⁹Ω. It can release static charges generated during movement in real time, preventing static electricity from damaging the platform’s precision circuit boards and sensors.

High-Elastic Coating Structure for Stable and Quiet Movement: The 3-5mm thick polyurethane coating layer has excellent shock absorption performance, which can absorb vibrations caused by uneven ground (vibration amplitude can be controlled within 0.1mm). This not only improves patient comfort during movement but also prevents equipment positioning deviation due to vibration.

2. Surgical Robots & Auxiliary Equipment: Strong Support of Polyurethane Coated Wheels – "High Precision + High Cleanliness"

Surgical robots and supporting equipment (such as instrument carts and robotic arm bases) have strict requirements for wheel "guidance precision" and "cleanliness" to ensure surgical safety and operational accuracy. Polyurethane coated wheels meet this high standard through detailed design:

Precision Coating Process to Ensure Zero Deviation: Adopting an integrated mold-forming polyurethane coating process, the thickness error of the wheel coating is ≤0.1mm. Combined with the coating surface with a low friction coefficient (friction coefficient ≤0.08), the surgical robot base and instrument cart can move along a fixed path with a deviation controlled within 0.5mm, ensuring the precision of robotic arm operations.

Non-Porous Coating Surface to Adapt to Aseptic Environment: The surface of polyurethane coated wheels is dense and non-porous, not absorbing dust, blood stains, or disinfectant residues. It can withstand 121℃ high-temperature sterilization or wiping with alcohol and chlorine-containing disinfectants. After each use, it only needs simple cleaning to restore a clean state, meeting the aseptic requirements of operating rooms.

Wear-Resistant Coating Material to Extend Service Life: High-wear-resistant polyurethane raw materials are used (wear rate ≤0.05cm³/1.61km). Even if the surgical equipment moves more than 100 times a day, the coated wheels can maintain stable performance for 3-5 years, reducing the frequency of equipment maintenance.

3. Conveyor Wheels for Testing Instruments: Strong Guarantee of Polyurethane Coated Wheels – "Corrosion Resistance + Low Pollution"

In clinical laboratories, the conveyor systems for samples (such as blood and urine) and reagents require wheels that can withstand frequent chemical contact and maintain cleanliness. Polyurethane coated wheels are the ideal choice:

Chemical-Resistant Coating Layer to Resist Various Reagents: Polyurethane coated wheels can resist erosion by common laboratory disinfectants (such as alcohol and hydrogen peroxide) and reagent spills. They do not crack or swell after long-term contact, ensuring the conveyor wheels do not fail due to chemical corrosion.

Low-Debris Coating Design to Eliminate Sample Contamination: By optimizing the polyurethane formula and production process, the amount of debris generated by the coated wheels during rolling is ≤0.1mg per 1000 rotations, which is far lower than the medical industry’s requirements for "low-pollution components". This prevents debris from mixing into samples such as blood and urine and affecting the accuracy of test results.

Customizable Coating Hardness to Adapt to Different Loads: According to the weight of samples on the conveyor (from 50g test tubes to 500g reagent boxes), polyurethane coating layers with a hardness of 60-90 Shore A can be customized. This not only ensures the supporting capacity of the wheels but also reduces the impact on sample containers through appropriate elasticity, preventing test tube breakage.

Get Medical-Grade Polyurethane Coated Wheel Solutions Now

If your medical equipment (CT/MRI auxiliary platforms, surgical robots, testing instruments, etc.) is looking for suitable high-stability and high-cleanliness coated wheels, or if you need customized polyurethane coated wheels with specific hardness and size, please feel free to contact us at any time! Add WhatsApp now: +86 19941574798, we will provide one-on-one technical consultation to help your medical equipment achieve safer and more accurate operation!

Categories

Recent Cases

Recent Products

Recent Blogs

- How Do Polyurethane Wheels Compare To Metal Wheels

- Why Choose Injected Polyurethane (TPU) Wheels for Your Equipment

- Why Roller Coasters Use NDI Polyurethane Wheels

- How to Choose a Poly Wheels Manufacturer That Won't Fail

- Why Polyurethane is the Choice for Pallet Jack and Forklift Wheels

- Pallet Stacker Drive & Idler Wheels for Automated Warehouses

- Mold-on Polyurethane Wheels

- Analysis of the Causes of Cleanroom Stacker Polyurethane Wheel

- Why Are NDI Drive Rollers the Premier Choice for Pallets

- Polyurethane Wheels in Mining

Poly Wheels for Aerospace Mobile Stairs

none