-

WhatsApp: +86 19941574798

WhatsApp: +86 19941574798

-

sale06@kfqizhongji.com

sale06@kfqizhongji.com

Special Equipment

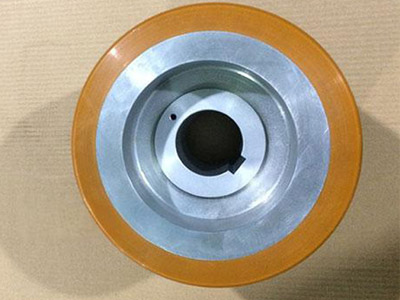

Airport Luggage Trolley Transfer Polyurethane Drive Wheel

Airport luggage trolley transfer polyurethane drive wheels facilitate the movement of luggage, cargo and equipment throughout the airport, carrying heavy objects while providing quiet, smooth and fast operation, durable and safe.

Airport luggage trolley transfer polyurethane drive wheels have emerged as a critical component of modern airport infrastructure. Combining durability, high performance, and safety, these wheels streamline the movement of luggage, cargo, and equipment across airports worldwide. This article explores the essential features that make polyurethane wheels ideal for airport trolleys and expands on their versatile applications across key airport systems.

Core Features of Polyurethane Wheels for Airport Trolleys

Airport trolleys face relentless use—navigating smooth terminal floors, rough baggage handling zones, and crowded corridors while bearing heavy loads. Polyurethane wheels are engineered to meet these demands with targeted advantages:

Exceptional Durability & Wear Resistance: Polyurethane’s inherent resistance to abrasion, dirt, and debris ensures wheels withstand constant movement and heavy loads without degradation. This extends trolley service life and reduces replacement frequency, lowering operational costs.

Superior Shock Absorption: The material’s elastic properties absorb impacts from uneven surfaces or obstacles, minimizing strain on trolleys and airport flooring. This prevents costly repairs to both equipment and infrastructure.、Noise Reduction: Unlike metal or plastic alternatives, polyurethane wheels deliver a quiet, smooth ride. This addresses the need for noise control in busy airports, enhancing comfort for passengers and staff.

High Load-Bearing Capacity: Engineered to support heavy weights, these wheels maintain stability and performance even when trolleys are fully loaded with luggage or cargo, ensuring safe transport.

Low Rolling Resistance: Polyurethane-coated wheels require less force to push or pull, improving maneuverability across long distances and crowded areas. This boosts efficiency for airport workers and eases use for passengers.

Versatile Applications Across Airport Systems

Beyond luggage trolleys, polyurethane wheels play a pivotal role in optimizing multiple airport operations, supporting efficiency and safety across diverse systems:

1. Baggage Handling Conveyor Systems

Polyurethane wheels are integral to conveyor systems that transport luggage from check-in counters to aircraft holds and baggage claim areas. Their durability and smooth rolling performance minimize jams and delays, directly enhancing the passenger experience by ensuring timely luggage delivery.

2. Passenger Boarding Bridges (PBBs)

Mobile passenger boarding bridges rely on polyurethane wheels for stable, seamless operation. Even when fully extended and supporting significant weight, these wheels provide the load-bearing capacity and smooth motion needed to connect terminals to aircraft safely.

3. Aircraft Ground Support Equipment

From pushback tugs and fuel trucks to baggage carts, polyurethane wheels equip essential ground support tools. Their high strength and stability enable reliable operation under challenging conditions, supporting critical pre-flight and post-flight processes.

4. Cleaning & Maintenance Equipment

Airport cleaning and maintenance tools—including floor scrubbers, vacuum cleaners, and maintenance carts—utilize polyurethane wheels. These wheels navigate diverse surfaces with ease while carrying heavy loads of cleaning supplies or tools, upholding airports’ strict cleanliness standards.

Why Polyurethane Wheels Are Indispensable for Modern Airports

Polyurethane-covered wheel sets are the unsung heroes of airport efficiency. Their unique combination of durability, shock absorption, noise reduction, and load-bearing capability makes them the ideal solution for the demanding airport environment. As airports expand and modernize—adopting smarter infrastructure and handling higher passenger volumes—polyurethane wheels will remain a critical component. From luggage trolleys to ground support systems, they ensure seamless, safe, and cost-effective operations, supporting both passenger satisfaction and staff productivity.

Categories

Recent Cases

Recent Products

Recent Blogs

- How Do Polyurethane Wheels Compare To Metal Wheels

- Why Choose Injected Polyurethane (TPU) Wheels for Your Equipment

- Why Roller Coasters Use NDI Polyurethane Wheels

- How to Choose a Poly Wheels Manufacturer That Won't Fail

- Why Polyurethane is the Choice for Pallet Jack and Forklift Wheels

- Pallet Stacker Drive & Idler Wheels for Automated Warehouses

- Mold-on Polyurethane Wheels

- Analysis of the Causes of Cleanroom Stacker Polyurethane Wheel

- Why Are NDI Drive Rollers the Premier Choice for Pallets

- Polyurethane Wheels in Mining

Polyurethane-Coated Conveyor Rollers

Electrical Monorail System (EMS) Polyurethane Friction Drive Wheel