-

WhatsApp: +86 19941574798

WhatsApp: +86 19941574798

-

sale06@kfqizhongji.com

sale06@kfqizhongji.com

Material Handling Drive System

Dust-Free Anti-Static Vulkollan Wheels in Stacker Cranes

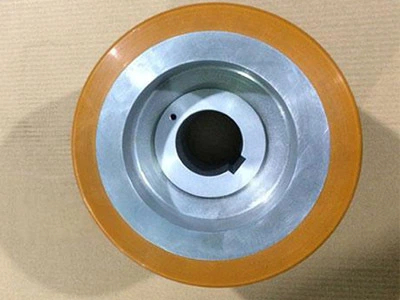

Vulkollan® wheels are essential components in stacker cranes, offering high load capacity, wear resistance. Used as drive wheels, guide wheels, and lifting rollers, they are used in automated warehouses and heavy-duty industrial systems.

In modern logistics and automated storage systems, stacker cranes play a crucial role in moving goods efficiently within high-rack warehouses. Among their key components, Vulkollan® wheels are essential for ensuring smooth operation, durability, and precision. Known for their outstanding performance, these wheels are widely used in stacker crane systems for various functions. Let’s explore the types, functions, and importance of Vulkollan wheels in stacker crane applications.

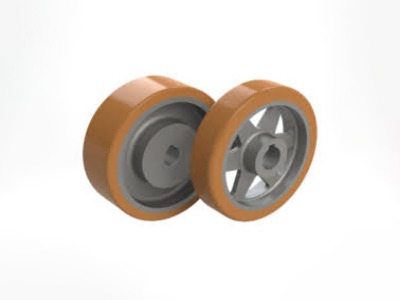

Types of Vulkollan® wheels used in stacker cranes

• Travel drive wheels

These heavy-duty wheels are responsible for driving the stacker crane along the track. Vulkollan’s high load-bearing capacity and abrasion resistance ensure stable and long-lasting travel performance.

• Track guide wheels

Also known as polyurethane guide wheels, these are often used alongside travel wheel blocks to prevent deviation during operation. Their high elasticity and precision help the stacker crane stay aligned with its track, reducing wear and improving reliability.

• Load platform guide wheels

Vulkollan® wheels are used on loading platforms to offer stable support during loading and unloading operations. Their low rolling resistance ensures smooth lateral or vertical movement.

• Lifting mechanism wheels

In the lifting assemblies of stacker cranes, these wheels act as guidance and support rollers, absorbing impact and allowing accurate positioning of the lifting frame.

Functional advantages of Vulkollan® wheels

Exceptional wear resistance: Vulkollan® provides outstanding resistance to abrasion, even under constant, heavy-duty use.

Oil, grease, and chemical resistance: Ideal for industrial environments where exposure to lubricants or contaminants is frequent.

Shock absorption & noise reduction: Their elastic nature helps dampen vibrations and reduce operational noise.

Temperature stability: Suitable for both cold storage and high-temperature operations.

Customizable hardness: Vulkollan® wheels can be tailored in hardness (typically 75–95 shore a) to meet specific performance needs.

Why vulkollan® wheels are essential for stacker cranes?

Stacker cranes operate at high speeds and carry heavy loads, often in 24/7 warehouse environments. Vulkollan wheels ensure:

Operational stability: Precision guidance and tracking minimize derailments and structural wear.

Long-term cost efficiency: Their durability reduces maintenance frequency and downtime.

Consistent performance: They maintain their mechanical properties over time, even under harsh working conditions.

From travel drive wheels to guide and lifting rollers, Vulkollan® wheels are vital to the performance and reliability of stacker cranes. Their unique material properties—combined with intelligent design—make them the preferred choice for industrial automation, especially in logistics, warehousing, and manufacturing sectors where reliability and precision are non-negotiable.

Categories

Recent Cases

Recent Products

Recent Blogs

- Why Choose Injected Polyurethane (TPU) Wheels for Your Equipment

- Pallet Stacker Drive & Idler Wheels for Automated Warehouses

- Mold-on Polyurethane Wheels

- Analysis of the Causes of Cleanroom Stacker Polyurethane Wheel

- Why Are NDI Drive Rollers the Premier Choice for Pallets

- Polyurethane Wheels in Mining

- How Do You Maintain Polyurethane Wheel Longevity

- How Do Polyurethane Wheels Compare To Metal Wheels

- What Industries Benefit Most From Using Polyurethane Industrial Wheels

- Polyurethane Forklift Wheels for Warehousing Pallet Handling

High-speed AGV Wheels in Automobile Production Lines

High-performance Polyurethane AGV Drive Wheels