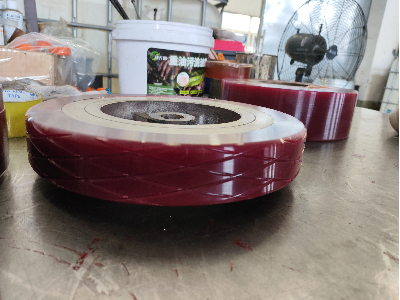

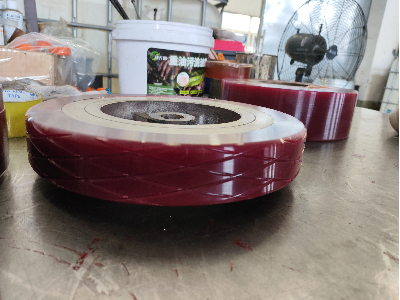

Anti-Skid Polyurethane Wheels for Cold Storage

Anti-skid polyurethane wheels for cold storage offer high traction, cold resistance, and durability, preventing slippage and wear while ensuring safe, smooth operation in sub-zero warehouse environments.

Technical Information

Cold storage environments are among the most challenging workplaces for material handling equipment. Temperatures often remain far below freezing, and humidity control is critical. In such conditions, equipment wheels must not only carry heavy loads but also maintain traction, flexibility, and durability despite extreme cold. Anti-skid polyurethane wheels are the ideal choice for these applications, offering dependable performance where conventional wheels may fail.

Key characteristics of non-slip polyurethane wheels

High traction in low temperatures: Special tread designs and optimized polyurethane formulations prevent slipping on icy or frosty floors.

Cold-resistant material: Maintains elasticity and load-bearing capacity even at sub-zero temperatures without cracking or hardening.

Excellent abrasion resistance: Withstands repeated travel over cold, hard surfaces without excessive wear.

Quiet and smooth operation: Reduces noise levels in confined cold storage areas, improving operator comfort.

Chemical and moisture resistance: Polyurethane resists water, cleaning agents, and certain chemicals used in cold storage hygiene routines.

Common wheel problems in cold storage

Loss of traction: Standard wheels can become slippery, increasing the risk of accidents.

Material hardening: Rubber or low-quality plastics can lose flexibility, leading to cracking.

Increased wear: Frost and grit can accelerate surface damage.

Bearing seizure: Condensation and freezing temperatures can cause bearing components to seize or corrode.

How polyurethane wheels avoid these issues

Anti-skid tread design: Customized patterns and grooves enhance grip on cold, smooth floors.

Low-temperature formulation: Specialized polyurethane blends maintain their mechanical properties in extreme cold.

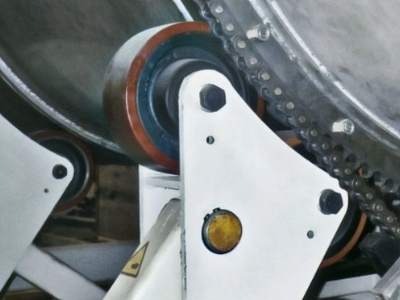

Sealed bearing systems: Protect bearings from moisture ingress and freezing damage.

Durable construction: High load capacity with excellent cut and tear resistance reduces premature failures.

Application scenarios

Cold storage warehouses: For transporting frozen goods between storage racks and loading bays.

Refrigerated distribution centers: Ensures stability and safety during pallet transfers in sub-zero areas.

Food processing facilities: Meets hygiene and durability standards in wet, cold environments.

Pharmaceutical cold rooms: For moving sensitive materials requiring strict temperature control.

Anti-skid polyurethane wheels are engineered to keep operations running safely and efficiently in the most demanding cold storage settings. Their combination of traction, resilience, and durability makes them an essential upgrade for any cold environment material handling fleet.

You have questions, we have answers. Contact us today. Our skilled customer service specialists can help you make the right choice in polyurethane applications.

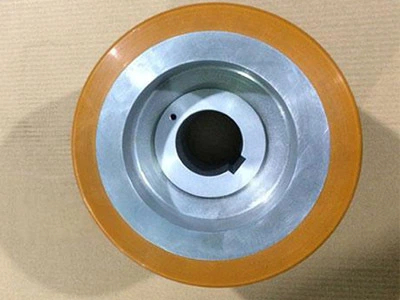

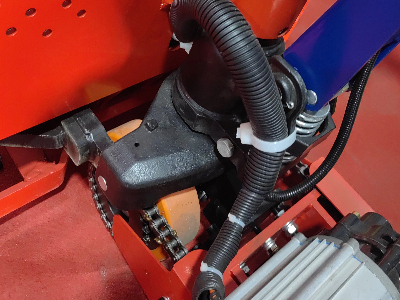

VULKOLLAN Wheel for Electric Pallet Stacker

none