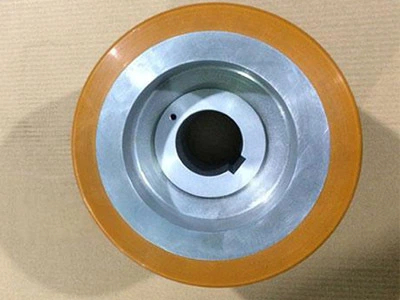

Polyurethane Single Flange Rail Wheels for Amusement Equipment

Polyurethane single flange rail wheels are specifically engineered to deliver low-noise, high-load, and smooth-rolling performance for rail-based amusement rides.

Technical Information

In amusement equipment where speed, safety, and passenger comfort are paramount, the choice of wheels is crucial. Polyurethane single flange rail wheels are specifically engineered to deliver low-noise, high-load, and smooth-rolling performance for rail-based amusement rides. Designed for loads of 1–1.5 tons per wheel and operating speeds up to 2.8 m/s, these wheels are ideal for track-guided amusement applications such as track trains and thrill rides.

Why use a single flange design?

The single flange design is commonly selected for rail-guided amusement equipment for the following reasons:

• Lateral guidance: The flange ensures the wheel remains properly aligned on the track, preventing derailment during rapid curves or elevation changes.

• Simplified maintenance: Compared to double flange or fully enclosed wheel sets, single flange wheels are easier to inspect and replace.

• Reduced rolling resistance: Only one side contacts the rail wall, minimizing friction and ensuring smoother, faster operation.

This design is particularly effective in closed-loop track systems, where the rail structure itself controls direction, and minimal steering correction is required from the wheelset.

How to achieve low noise at high speeds?

Amusement rides often operate in urban entertainment zones or indoor environments where excessive mechanical noise is undesirable. These polyurethane rail wheels are optimized for quiet operation through the following features:

• Elastic polyurethane tread: The polyurethane layer absorbs vibrations and reduces rolling noise compared to metal or hard plastic wheels.

• Precision machining: High concentricity of the tread surface ensures even contact with the rail, avoiding vibration-induced noise at high speed.

• Shock-absorbing design: The urethane acts as a buffer between the rail and the wheel core, softening impacts during acceleration, deceleration, or over joints.

• Silent bearing system: Quality sealed bearings with minimal clearance and noise-damping grease ensure smooth, quiet rotation.

How does the wheel core support heavy loads?

With individual wheels supporting 1 to 1.5 tons, the wheel core material plays a key role in structural integrity and safety:

• High-strength steel or cast iron core: The internal hub is designed to handle extreme radial loads without deformation. It provides a secure mounting interface for axles and bearings, even under dynamic forces.

• Reinforced bonding with polyurethane: Advanced molding and bonding techniques ensure the polyurethane tread remains firmly attached, resisting delamination under load or speed.

• Built-in structural ribs or keyed connections: These ensure that torque and load are evenly transferred through the wheel during motion, reducing the risk of slippage or fatigue over time.

In rides with high g-forces and fast transitions, the mechanical stability of the core is vital for long-term safe use.

Applications in amusement equipment

These polyurethane single flange wheels are widely used in:

• Track-guided roller coasters

• Indoor rail rides and scenic trains

• Rotating or orbiting amusement structures

• Compact thrill rides on precision rails

• Theme park shuttles or carts

Their combination of load-bearing performance, quiet operation, and precision tracking makes them a top choice for ride engineers focused on safety and user experience.

For modern amusement systems that demand silent operation, speed, and safety, polyurethane wheels provide a reliable and efficient solution. With durable cores, precision construction, and noise-reducing materials, these wheels ensure smooth, quiet rides that your passengers can enjoy — and your maintenance team can rely on.

You have questions, we have answers. Contact us today. Our skilled customer service specialists can help you make the right choice in polyurethane applications.

Vulkollan® Heavy-Duty Industry Wheels

none