- +86-19941574798

- sale06@kfqizhongji.com

Semiconductor Workshop Equipment

Application of Clean Room Aluminum Core Polyurethane Wheels on Mobile Gantry Cranes

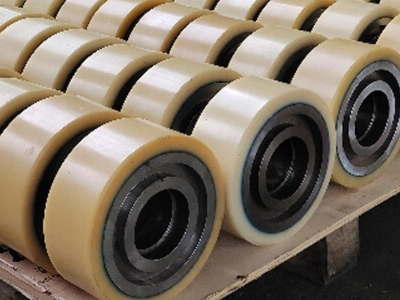

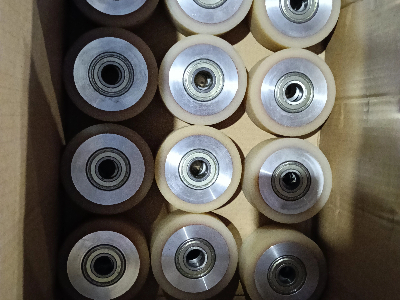

Aluminum core polyurethane universal wheels have the characteristics of being dust-free, static-free, with no chipping, quiet, shock-absorbing, lightweight, and high strength.

Aluminum alloy gantry cranes are widely used in clean room environments (such as semiconductors, medicine, biological laboratories, etc.) due to their lightweight, corrosion-resistant, and low-pollution characteristics. Aluminum core polyurethane travel universal wheels have the characteristics of being dust-free, static-free, with no chipping, quiet, shock-absorbing, lightweight, and high strength, and are suitable for use in mobile gantry cranes in industries such as semiconductors, medicine, biological laboratories, pharmaceuticals, and avionics. This article will introduce in detail the design features, selection reasons, and usage precautions of aluminum core polyurethane wheels.

1. Reasons for choosing aluminum core polyurethane universal wheels

● Adaptability to a clean room environment

Low pollution: Polyurethane (PU) material does not shed dust, meeting the dust prevention requirements of clean room ISO Class 1-8.

Antistatic: Customizable antistatic formula to prevent static electricity accumulation from affecting precision instruments or electronic components.

● Lightweight and high load-bearing

Aluminum core structure: Compared with cast iron or steel core, the aluminum core is lighter (reducing crane load) while maintaining high strength, suitable for the lightweight design of aluminum alloy gantry.

Polyurethane rubber coating: Provides excellent load-bearing capacity (single wheel can reach 1-5 tons), and elastic buffering can reduce equipment vibration.

● Wear resistance and low noise

High wear resistance: The wear resistance coefficient of polyurethane is 3-5 times that of rubber, which prolongs the life of the wheel and reduces the frequency of replacement.

Quiet operation: Polyurethane elastomer can absorb impact and reduce noise during movement (<65dB), suitable for clean environments that are sensitive to noise.

● Chemical corrosion resistance

Polyurethane is oil-resistant, weak acid-resistant, and alkali-resistant, and is suitable for clean room scenarios where it may come into contact with detergents or chemical reagents.

● Universal swivel wheels

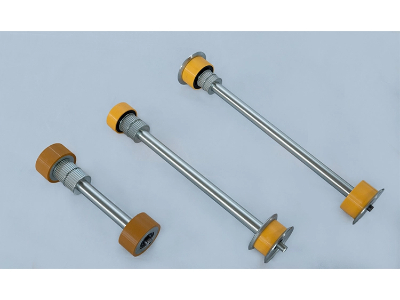

Can rotate 360 degrees to adjust the mobile position

2. Design features

● High-precision processing

The aluminum wheel core is processed by CNC to ensure precise matching with the gantry crane bearing system, smooth operation, and no sway.

● Polyurethane casting process

Using high-performance wear-resistant polyurethane material, the aluminum core is firmly coated by a hot casting + vulcanization process to ensure that it will not debond or crack after long-term use.

● Arc wheel surface design

According to the use characteristics of the gantry crane, the wheel surface is mostly designed with an arc shape or a small R angle to reduce the starting resistance and facilitate smooth propulsion.

● Anti-corrosion treatment

The surface of the aluminum core is anodized to improve corrosion resistance and is suitable for high humidity or mild chemical gas environments.

● Customized options

Color: Clean room polyurethane wheels with different load-bearing capacities, different sizes, different structures, and different materials can be provided.

Conductive/anti-static type: The surface resistance is adjustable (10^4–10^9 Ω) to meet ESD protection requirements.

3. Precautions for use

● Load matching

The load-bearing capacity of a single wheel must be calculated based on the total weight of the crane (including the load) to avoid overloading that may cause deformation of the wheel or damage to the bearing.

● Ground conditions

Ensure that the ground is flat and free of sharp foreign objects. Although polyurethane wheels are wear-resistant, hard objects may still scratch the wheel surface.

● Maintenance and inspection

Regularly lubricate the bearings: It is recommended to check the bearing condition every 3-6 months and use food-grade grease (suitable for clean rooms).

Wheel surface wear monitoring: When the polyurethane layer is worn to the point where the aluminum core is exposed, it must be replaced immediately to avoid metal contact and damage to the ground.

● Environmental restrictions

Avoid long-term exposure to ultraviolet rays or high temperatures (>80°C) as this may cause polyurethane aging.

Specially formulated polyurethane materials must be used in strong acid and alkali, high temperature, and low temperature environments.

Aluminum core polyurethane wheels have the advantages of lightweight, high load-bearing capacity, and low pollution, making them an ideal choice for aluminum alloy gantry cranes in clean room applications. Through reasonable selection (such as load, conductivity requirements) and standardized maintenance, the stability of the equipment can be significantly improved, and the service life can be extended.

If you need technical parameters or drawings, please contact us.

Categories

Recent Cases

Recent Products

Recent Blogs

- How Vulkollan® Wheels Enhance Stacker Performance

- Polyurethane Drive Wheel Casting Process Analysis

- Advantages of VULKOLLAN AGV Wheels

- High-Quality Polyurethane Fork Wheels from China Manufacturer

- Why More Warehouses Are Switching to Polyurethane Pallet Wheels

- Advantages of Polyurethane Tread Heavy-Duty Wheels with Cast Iron Core in Industry

- Advantages of Anti-Skid Polyurethane Wheels in the Food Industry

- What Are the Advantages of Vulkollan AGV Guide Wheels

- Advantages of Vulkollan Polyurethane Load-Bearing Wheels in Automatic Parking Garages

- Analysis of the Causes of Cleanroom Stacker Polyurethane Wheel Powdering and Degumming

Photolithography Machine Polyurethane Guide Wheel

Application of Cleanroom Semiconductor Stocker Polyurethane Drive Wheel